Restored d17 project

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=207829

Printed Date: 05 Feb 2026 at 1:43am

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: Restored d17 project

Posted By: 55allis

Subject: Restored d17 project

Date Posted: 17 Aug 2025 at 7:45am

|

Blessed Sunday morning Just got this d17 in that does not turn over at all and I’m guessing that it’s the crank seals are the culprit due to that being the last thing that was done to it. It has been fully redone inside out supposedly. I thought that I’d post on here from the start to finish so that it’s on the record. Btw the rear crank seal is still leaking…..  ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Replies:

Posted By: DrAllis

Date Posted: 17 Aug 2025 at 7:57am

| That's a bad deal. I figured he'd have someone else (competent) fix it right and keep it after all the $$$$$ spent on it. |

Posted By: 55allis

Date Posted: 18 Aug 2025 at 6:01pm

|

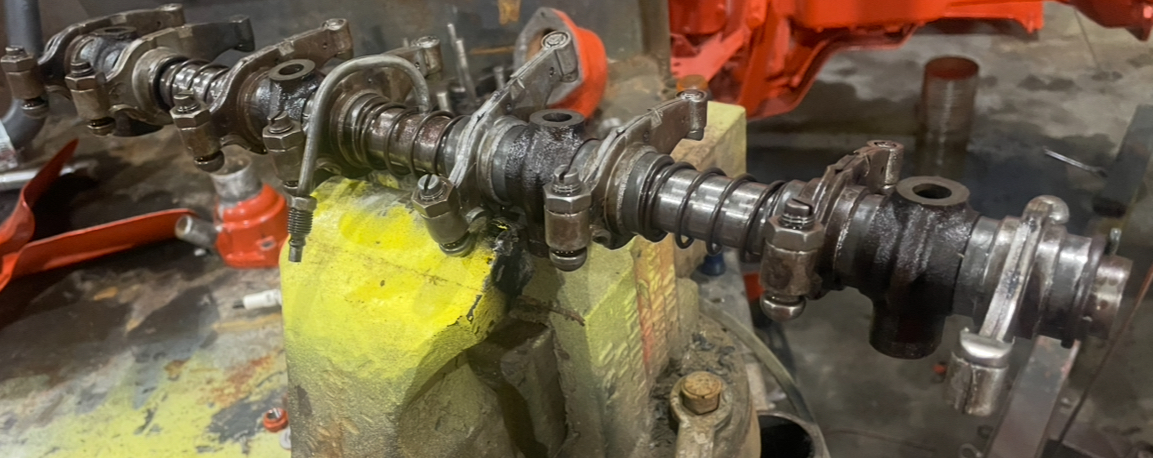

Update: found that all 8 push rods are bent and I call shot… The rear crank seal leak ended up being the gasket had fell into the oil pan.    Anything else I should check? I’m going to re-torque everything just to be safe. What are the common problems that cause pushrod bending? Don’t want it to do it again… ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: plummerscarin

Date Posted: 18 Aug 2025 at 6:23pm

| In my case, the valves hung up in the head. Bent pushrods, bent valves, and left a mark in the piston where they made contact. Might even consider having the rods inspected as well. |

Posted By: 55allis

Date Posted: 18 Aug 2025 at 6:32pm

|

Here is the original thread about it. https://www.allischalmers.com/forum/topic207217_post1773954.html#1773954" rel="nofollow - https://www.allischalmers.com/forum/topic207217_post1773954.html#1773954 ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: steve(ill)

Date Posted: 18 Aug 2025 at 6:50pm

|

hard to believe that EVERY VALVE was stuck.. but possible... I would check the CAM TIMING... that would effect ALL valves hitting the pistons.... checking the rods for any BEND would be a good idea. ------------- Like them all, but love the "B"s. |

Posted By: Les Kerf

Date Posted: 18 Aug 2025 at 8:29pm

X2 The previous thread linked above gave no indication as to whether or not this engine ever ran at all and no clues as to what type of 'overhaul' was done. Wrong pistons? Increased stroke? Shaved head? High-lift cam? Timing gears thrown in there haphazardly?  I dunno, I wonder who does?

|

Posted By: 55allis

Date Posted: 18 Aug 2025 at 8:57pm

|

Funny thing is I don’t see any damage to the pistons or valves… ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: Bingo8

Date Posted: 18 Aug 2025 at 9:02pm

| Oh, I am keeping it. 55Allis is helping me out. It was an unfortunate situation. Unfortunately, I am not sure what I could have done differently when choosing him to restore it. He came highly recommended, has his work in magazines, and put clinics on for tractor restoration. Seemed like the right guy at the time. Hindsight is 20/20 but I am moving on with someone who hopefully can get it fixed up. |

Posted By: 55allis

Date Posted: 18 Aug 2025 at 9:23pm

Found these numbers on on piston; AE 233 Maybe a brand and part number? ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: SteveM C/IL

Date Posted: 18 Aug 2025 at 11:03pm

| Bout have to be cam out of time unless they're all stuck |

Posted By: 55allis

Date Posted: 18 Aug 2025 at 11:40pm

|

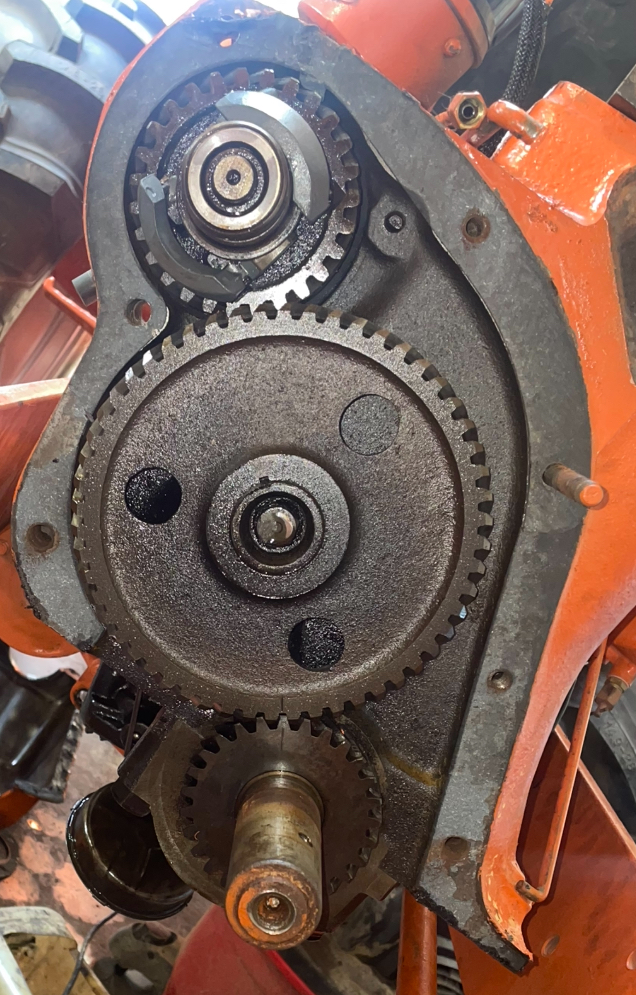

I’ll remove the timing gears cover and check it out. Think I’m still going to have to split the tractor due to a hydraulic leak in the clutch housing. Thanks!! ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: DrAllis

Date Posted: 19 Aug 2025 at 6:41am

| There's something going on with that engine. It was a running engine !! That's why the rear seal was leaking...it RAN !! All 8 push rods bent on a running engine?? Makes you think the camshaft quit turning. |

Posted By: Les Kerf

Date Posted: 19 Aug 2025 at 8:15am

|

Could the governor fail and send debris into the timing gears and cause the cam to lock up? |

Posted By: DrAllis

Date Posted: 19 Aug 2025 at 8:42am

| Worn governor weights and timing gear damage are two things that go together. Maybe, just maybe, the governor weights blew apart while the engine was running AND no one was sitting on the seat to shut off the key ?? That might xplain the carnage. And as far as the man who restored this tractor goes, he might very well be the great restorer of SOME BRANDS of tractors, but certainly not a D-17 Allis-Chalmers. I can't imagine tackling multiple brands for restore projects and ever hope to be very successful at it. The nuances and quirks of each particular brand and model keeps most of us busy when repairing/rebuilding things. |

Posted By: Les Kerf

Date Posted: 19 Aug 2025 at 9:21am

...AND maybe the guy WAS sitting in the seat and reached around with a broomstick and shoved the throttle wide open on the carburetor...   I spent 30 years in sawmill maintenance, and the single most difficult part about troubleshooting equipment problems was getting accurate, and COMPLETE information about what actually happened. What did you see? What did you hear? What was the machine doing immediately prior to the wreck? What was changed/adjusted? Etc.

|

Posted By: 55allis

Date Posted: 19 Aug 2025 at 1:45pm

|

So now I’m even wondering if he ever had it running… Spark plugs are new and never ran on (he claims put new ones after he ran it) Pistons still have grease on top. Crank pulley doesn’t have any paint/rust wore off from the belt. ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: HudCo

Date Posted: 19 Aug 2025 at 2:43pm

|

Posted By: DrAllis

Date Posted: 19 Aug 2025 at 6:55pm

| Here's another good example of poor information. One of our younger field tech's was out working on an old Cat 988 wheel loader. The unit had around 50,000 total hrs on it. The complaint was a "may-day" sudden loss of engine power. Just started doing it too. Can't even use it, it's sooo bad. The Tech called me for some elderly advice. He said the engine starts and runs fine, but maximum turbo boost was 3 to 4 lbs low of factory specs. I told him that I think the injection pump is probably getting tired, and the complaint of it "just started doing this" isn't true. I suggested that he give the fuel delivery screw a turn or turn and a half outward and see if the boost improves. I also told him to grill all affected employees at this quarry about the machines power as of late. In the end, the boost went up. Engine HP was now where it should have been. The "lie" was that the performance has been somewhat weak for a year or more. This particular day the operator was "new" to this machine. |

Posted By: Les Kerf

Date Posted: 19 Aug 2025 at 7:27pm

|

DrAllis, that is iggzackly what I was referring to  I have never so much as touched a D17 Allis-Chalmers; is there anything really basic in the timing gear train that could have been left undone? Something really stupid like forgetting to tighten a nut or leaving a cotter pin out? Thereby allowing parts to fall off and cascade into catastrophic failure? |

Posted By: 55allis

Date Posted: 19 Aug 2025 at 9:07pm

|

Here is a picture of the sheet I got of what he supposedly did to it. It wouldn’t let me post a picture of it but it copied it. Allis Chalmers D-17 Statement of Repairs • Decals/Nose Emblem • Clutch Assembly (All) disc & pressure plate replaced • Replace Throw Out Bearing • Changed out Clutch Shaft • New Piston Rings • New Bearings • New Gaskets • Rebuilt Head-ground valves • Rebuilt Carburetor • Rebuilt Hydraulic Pump • Rebuilt Water Pump • Rebuilt Governor • Flushed and repaired radiator • New Rim on Rear End (1) • Replaced Front Rim (Used)(1) • Sand blasted rims and sheet metal • Painted entire Tractor • Split tractor 3 times • Rebuilt the head twice • Cleaned and Sealed Gas Tank • Replaced rear axle seals • New Brakes and seals • New wire harness and wiring • New Gauges and switches • New Steering Wheel • New Muffler • Switched from Generator to alternator • New points, plugs, condenser and cap • New Tires front and rear-with tubes • Starter Rebuilt • Replaced all hoses and clamps • Replaced Fan Belt • Replaced lights and or bulbs as needed • Seat Cover • Antifreeze, Oil, Rear End Oil, Hydraulic Oil • Oil Filter • Fly Wheel Ring Gear • Sediment Bowl • Shifter Boot ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: 55allis

Date Posted: 19 Aug 2025 at 11:06pm

|

Would it still leave marks on the pistons if it was slowly getting turned over? Like if someone tried to pull start it? Or is it just lucky and didn’t leave marks…. I’m just plump curious on why there is no marks anywhere that I can find. ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: TedN

Date Posted: 20 Aug 2025 at 12:22am

|

I notice in the statement of repairs that the head was rebuilt-ground valves and the head was rebuilt twice. Just a guess on my part but it probably didn't run enough hours during the restoration process to need the head rebuilt the second time, so there was probably something not quite right the first time it was done. I think I would at least ask. Not always fun stepping in at the end to try to figure out why a job wasn't finished. How much of the previous work do you assume was done correctly? And of couse how and why did all of the pushrods get bent so severely? I think maybe there was some factor in the first rebuild that caused coil bind in the springs(wrong springs?) and the pushrods were bent then, and either not replaced or they were "straightened" but still bent enough to be weakened so they bent shortly after it fired, but again just a guess on my part. Ted ------------- 190XTD seriesIII, 190XTD seriesI, maroon belly 7000, 190XTD series??? project(or maybe parts) |

Posted By: Jason (IN)

Date Posted: 20 Aug 2025 at 6:06am

| Makes me wonder if the push rods were even engaging the lifters. |

Posted By: Les Kerf

Date Posted: 20 Aug 2025 at 7:40am

Probably not. The valves come straight down in such a manner that the sharp edges will not cut into the piston unless the velocity is pretty high. Way back in my youth I did a ring and valve job on a Datsun 1600 cc overhead cam engine. In my ignorance I paid no attention to where the cam and crank phasing was and I just bolted the head on, then rotated the crank around to line up the timing marks. I felt a slight 'bump' of resistance while doing this but thought it was just the new rings dragging. Before I re-installed the engine I rotated it using a wrench, stuck my finger in the spark plug holes and found no compression on two cylinders. Yup, it bent the valves. Even though those valves contacted the pistons at an angle there were no discernible marks.

|

Posted By: Les Kerf

Date Posted: 20 Aug 2025 at 7:46am

Add labor to that and it will be pushing nigh unto $10G

|

Posted By: DrAllis

Date Posted: 20 Aug 2025 at 7:49am

| It will be interesting to get the timing cover removed and verify that the cam gear and crank gear are actually in time (or not). I've seen a lot of things in the last almost 60 years, but eight bent pushrods in a 4-cylinder engine isn't one of them. |

Posted By: Les Kerf

Date Posted: 20 Aug 2025 at 7:57am

You have a good point there  This would also explain why there are no marks on the pistons and it would not bend the valves.

|

Posted By: tbran

Date Posted: 20 Aug 2025 at 8:09am

|

Check the valve guides. We had one do the same thing. The guides were not pressed down to specs and the result was the keepers were hitting the guides . Head shop misread the specs. ------------- When told "it's not the money,it's the principle", remember, it's always the money.. |

Posted By: DrAllis

Date Posted: 20 Aug 2025 at 8:27am

| Well, I will share something that happened to me a couple of years ago. I've got a One-Seventy gas tractor. It had been overhauled by someone probably less than 500 hrs before i bought it. It was a poorly done "in-chassis" OH. The engine had a slight thump or noise when it idled after getting warmed up. I tolerated that for the first summer of tractor riding and the next winter pulled the engine out to fix the badly leaking rear crankshaft seal. Well, the noise was the thrust surface on the crank was totally destroyed and the crank had about 1/8" of endplay. This being due to (I assumed) someone many moons ago not keeping the clutch pedal adjusted for freeplay. So, I had another crankshaft, got it reground to -.010"/-.010" and stuck it in the block from underneath. At the same time, I installed the last known new 175 camshaft that exists !! Why not ?? Pretty easy to do at that point. So, new mains, rods and cam bearings and a higher lift 175 camshaft. What a combo !! I had run a compression test before ever beginning work on the bottom end and it was OK fine. So, mid-summer of tractor rides and the engine dropped the #1 exhaust valve at full throttle going down the road with 30 other tractors following me. It destroyed the cyl head. It poked a hole in the piston top. It also had the rocker arm to that valve destroyed as well with metal flakes everywhere around the front of the cylinder head. What the Sam Hill has happened here ?? It took me a bit to finally connect all the dots, but the knuckle head that did many other things wrong on the engine OH didn't have that particular VALVE GUIDE pressed in the head as far as it should have been !!!!! So, with the installation of the higher lift 175 camshaft, the valve rotator was just kissing the top of the valve guide, eventually knocking the keepers loose at high RPM's and dropping the valve. So, I've been dealing with metal in the oil from that failure 2 years ago and even with magnets in the oil pan, I now hear the center main bearing pound whenever I start the engine cold until the oil pressure light goes out. Soooo, back to EIGHT bend pushrods..........better be sure the valve guides are installed at the proper depth !!!!!! I never bend a push rod because it wasn't hitting hard, just kissing. But this D-17 engine??? Something is terribly wrong. |

Posted By: DrAllis

Date Posted: 20 Aug 2025 at 8:29am

| Took me 20 minutes to type my short story and TBran beat me to it !!! |

Posted By: SteveM C/IL

Date Posted: 20 Aug 2025 at 11:14am

| Lol there pokey....starting to look like guides may be the culprit. |

Posted By: TedN

Date Posted: 20 Aug 2025 at 11:18am

|

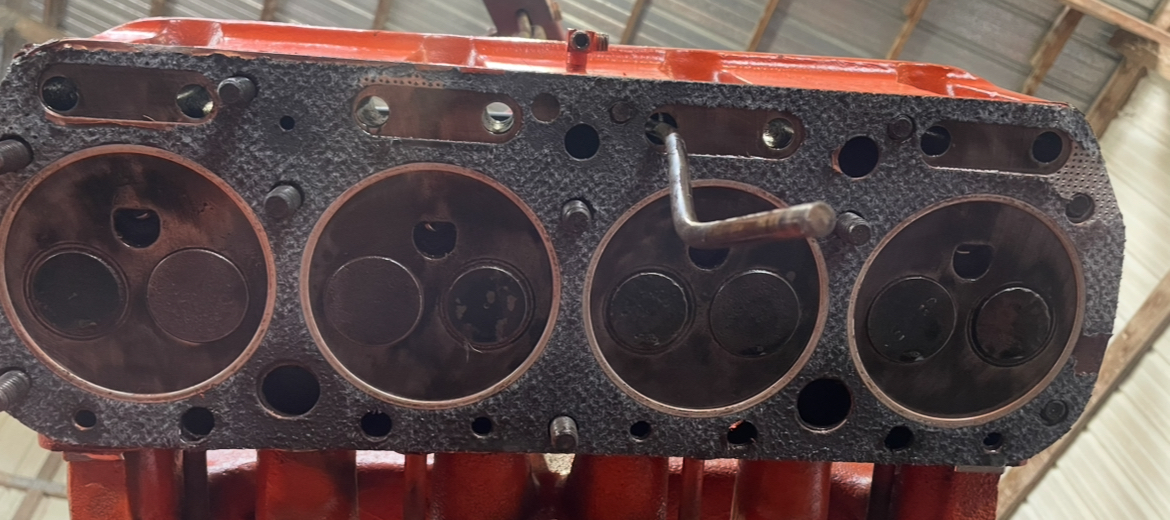

First post said it doesn't turn over at all - does it now turn with the head removed? It looks like the pistons are in different positions, so I would guess it does. I think I would bolt the head back on and see if I could get a pushrod straight enough to give a decent indication, then roll it over by hand until you see what stops it. I think the suggestion of valve guides is correct, because it would be difficult to time the cam to bend ALL of the pushrods so severely, maybe half of them. Be interesting to see the cause. Ted ------------- 190XTD seriesIII, 190XTD seriesI, maroon belly 7000, 190XTD series??? project(or maybe parts) |

Posted By: DrAllis

Date Posted: 20 Aug 2025 at 11:28am

| There's a dimension given in the service manual as to how far to press the valve guides in BELOW flush of the top surface of the cylinder head (where the valve cover gasket contacts). This is the most likely cause of 8 destroyed push rods. |

Posted By: Clay

Date Posted: 20 Aug 2025 at 11:30am

|

Improperly knurled or honed valve guides? Valve guide bores measured for the proper tolerance?

Condition of valve stems? Valve seat depth? Rust or deposits on the valves? Excess fuel or water in the cylinders? Engine way out of time? Mud daubers? Gremlins? These and many other mysteries need to be answered. |

Posted By: HudCo

Date Posted: 20 Aug 2025 at 11:36am

| my red flag is it said that the head was done twice it was split three times three places or the same place three times |

Posted By: 55allis

Date Posted: 20 Aug 2025 at 11:45am

|

The front crank pulley was never pulled… Was just about every thing my puller could pull without heating it up. The seal looks original. The engine does turn over after I got all the push rods out (that was really fun getting one out  ). ).The valve guides look to be good with being just pass even with top of head.    Valve that I pulled doesn’t appear to be in the best shape but looks like it should run. ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: DrAllis

Date Posted: 20 Aug 2025 at 11:52am

| I'd have to look in my service manual at home to tell you the guide height, but it's below flush of the top of the head, not flush. I'm thinking 1/8" inch below. When one used Allis/AGCO guides they had a mark on the guides that was the proper dimension so you pressed them into the head from the top until the mark was flush with the guides bore. |

Posted By: steve(ill)

Date Posted: 20 Aug 2025 at 12:15pm

|

that valve face looks like it was cut with a body grinder !! ....... is it just a bad picture, or is it really that bad ? ------------- Like them all, but love the "B"s. |

Posted By: Les Kerf

Date Posted: 20 Aug 2025 at 1:36pm

My 14 year old grandson does a better job than that using my 100 year old Van Norman valve grinder. Seriously.

|

Posted By: Gary Burnett

Date Posted: 20 Aug 2025 at 4:17pm

| The stem also looks like its an old valve not new one |

Posted By: 55allis

Date Posted: 20 Aug 2025 at 6:39pm

Just noticed today that the bottom of the sleeves are pitted pretty bad… If I was to planing on running it a lot I’d probably go ahead and put new sleeves in due to burning a little oil.  I didn’t realize that someone could do a job like this and still get business while charging full price.. ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: 55allis

Date Posted: 20 Aug 2025 at 6:42pm

He probably could run a paint gun a lot better than what this guy did too!!! The back wheels are full of runs… and the front axle was painted with a brush it looks like to me…. ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: DrAllis

Date Posted: 20 Aug 2025 at 7:02pm

| Intake guides to be at least 1/8" (.125") below flush with the top of the head and exhausts are flush. |

Posted By: Dirt Farmer

Date Posted: 20 Aug 2025 at 9:22pm

| Just wondering, what are the chances that the last time it was worked on the guy put the wrong push rods in out of another project he had been working on and there is another project out there that has no power or cranks but won't start. Just thinking outside the box. Too long, totally collapsing the spring and bending the push rods. |

Posted By: Gary Burnett

Date Posted: 21 Aug 2025 at 1:28am

Also seems to me I remember some of the rocker assemblies being different heights on the 201/226 motors.

|

Posted By: 55allis

Date Posted: 21 Aug 2025 at 11:35pm

|

Valve guides do not appear to have been replaced… But they don’t seem to be even… Plan is to go ahead and rebuild the head, going to local engine shop tomorrow and he will check and or replace valve seats, some appear to have pits and or sunk in. Some of the original valves have a little bend to them, not bad but figured with the rust pits that fresh ones won’t hurt it. Going to replace the clutch shaft seal and front crank seal due to leaking. Need your opinion, should I replace the rear crank seal again? The guy supposedly replaced it all ready…. Did he do it correctly I have no clue until I get it apart. ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: Dirt Farmer

Date Posted: 21 Aug 2025 at 11:57pm

| Better safe than sorry while you have it this far along and if it starts leaking he'd probably blame you. I'd try to figure out why the bent push rods before I dove in too deep. Could turn into a money pit but that's not on you, you are working with what you have and connecting the dots like any good mechanic would do. While the head is being checked over have them check it for being true and flat and ask if there is a way to measure if and how much it may have been planed down. Be sure to check valve/rocker arm settings when reassembling. Keep us in the loop cause we all learn something on here from others experiences. |

Posted By: Lynn Marshall

Date Posted: 22 Aug 2025 at 7:34am

| I'm sorry, but what a mess. If I scratch my head anymore over these problems, I'm gonna have another bare spot. Replaced clutch shaft and now the clutch shaft seal is leaking?? The head has supposed to have been went through twice already and looks like that?? As for the push rods, I don't think that the starter could have even turned the engine over after a piston hit the first valve. Maybe someone tried to pull start it and could have done the damage. It would still have to be seriously out of time with the cam position. If you're going to replace the front crank seal, I'd pull the front cover and have a look. |

Posted By: 55allis

Date Posted: 22 Aug 2025 at 8:44am

Looks to be in time.. Very confusing because front pulley doesn’t appear to have been removed and the seal too, but the gasket seems like it has gasket maker on it… I’m starting to get bald spots from scratching my head…. ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: Lynn Marshall

Date Posted: 22 Aug 2025 at 9:37am

| Is the #1 piston at top dead center in that photo? |

Posted By: steve(ill)

Date Posted: 22 Aug 2025 at 9:48am

|

cam is in time and the governor is OK...... and the valves bent... So valves were stuck in the guides, or the engine had oil on top of the pistons and came up on compression when full of fuel / oil ?

he said it was in the shop for 7 years... maybe the rings stuck in the piston and no compression, or stuck to liner and no rotation.. so they put a few oz of oil in each cylinder and let it set, then installed plugs without removing the oil ?? ------------- Like them all, but love the "B"s. |

Posted By: 55allis

Date Posted: 22 Aug 2025 at 11:13am

Yes it is ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: 55allis

Date Posted: 22 Aug 2025 at 11:18am

There only was some grease, in previous posts I had a picture of the cylinders right after I removed the head. I sprayed some JD multipurpose oil down the spark plug holes to prevent cylinder scoring when I got it here. But it was still stuck until I removed all the push rods. ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: Les Kerf

Date Posted: 22 Aug 2025 at 10:33pm

|

Even though the timing marks are lined up, at this point I would put a degree wheel on the crankshaft and verify the actual cam lobe events. I have seen engines that had the timing gears installed incorrectly. |

Posted By: 55allis

Date Posted: 22 Aug 2025 at 11:48pm

|

To me it looks like it has a key in the cam shaft, so there’s only one way for it to go on… I will look at the distributor and see if it’s right but I don’t think that the cam or cam gear has been removed… I could be wrong but I will look into that. I have the head in the head shop for inspection so it will probably take him a few days to do that. Hoping it won’t need anything but rather safe than sorry. ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: 55allis

Date Posted: 24 Aug 2025 at 12:28am

So I looked at the distributor and here’s what it looks like at tdc  ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: Lynn Marshall

Date Posted: 24 Aug 2025 at 6:41am

| The distributor is just what the name implies. It distributes the spark to the proper cylinder at the proper time. With the cap back on, the rotor should be pointing approximately, to the #1 cylinder wire. Nothing in the distributor is going to cause that carnage with the push rods. |

Posted By: DrAllis

Date Posted: 24 Aug 2025 at 7:00am

| TDC on #1 is also TDC for #4, only one full turn different. The problem ain't there. |

Posted By: 55allis

Date Posted: 24 Aug 2025 at 10:38am

|

I was meaning if the cam time was off the distributor could be off too… ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: DrAllis

Date Posted: 24 Aug 2025 at 11:06am

| Not necessarily. But if the cam timing to the crank was off, it probably wouldn't ever run regardless of where the ignition timing was. Late camshaft timing would result in the exhaust valves getting smacked when the piston was coming up and the exhaust valves aren't yet closed. This catastrophic failure of the valve train can only be from incorrect valve guide height. The cam/crank timing was correct. How could 8 valves be stuck in their guides?? very doubtful. |

Posted By: Les Kerf

Date Posted: 24 Aug 2025 at 11:11am

With the head off you can easily verify the cam timing without a degree wheel simply by putting the #1 piston at TDC, then look at the cam lobes. At the tail end of the exhaust stroke both lobes will be upward with the overlap split because the exhaust will be just closing and the intake will be just beginning to open. If the cam timing is off enough to matter then it will be obvious to the naked eye. This is probably not where the problem lies with this engine, but it is so easy to check that it is worth doing just so that you know it is correct.

|

Posted By: SteveM C/IL

Date Posted: 24 Aug 2025 at 12:37pm

| If the guides and caps aren't interfering and cam timing looks correct and guides weren't stuck about all that's left is rocker adjustment. So wait a minute...tall heads use short stands,short heads use tall stands...do we have short head short stands? |

Posted By: 55allis

Date Posted: 25 Aug 2025 at 9:31am

|

Does anyone have any pictures comparing the two? ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: 55allis

Date Posted: 25 Aug 2025 at 9:39am

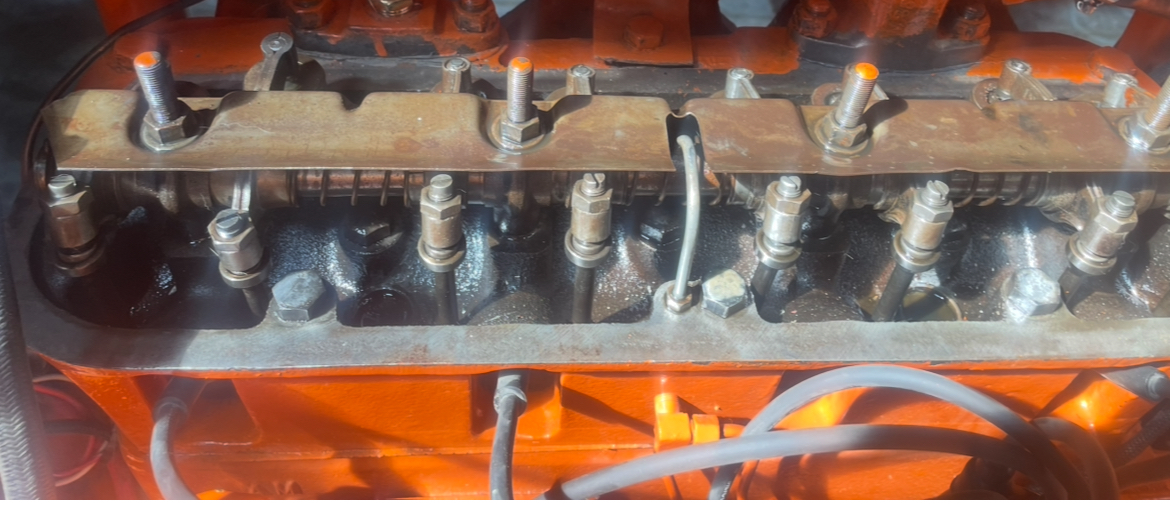

Here is a picture before I removed it. ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: DrAllis

Date Posted: 25 Aug 2025 at 10:00am

| I wonder if he had the rocker arm stands upside down ?? Long side goes down to the cyl head. |

Posted By: TedN

Date Posted: 25 Aug 2025 at 12:55pm

|

In that picture it looks like #4 intake is the only valve that is closed. I wasn't aware of two different pedestal heights that SteveM mentioned, but I was able to find a picture on Facebook of a D17 engine, and it looks like the pedestal mounts are about 1/2" taller. It also looks like there is a color change on the studs about 1/2" above the nuts in your picture, like maybe that is where the nuts used to be. I learn something new every day. Ted ------------- 190XTD seriesIII, 190XTD seriesI, maroon belly 7000, 190XTD series??? project(or maybe parts) |

Posted By: Les Kerf

Date Posted: 25 Aug 2025 at 8:09pm

I believe that would do it

|

Posted By: Mikez

Date Posted: 25 Aug 2025 at 8:39pm

|

Yea looks like the rockers are just about up against tray. How strong are the rockers after that.

|

Posted By: 55allis

Date Posted: 25 Aug 2025 at 9:54pm

Here’s a picture of the rocker currently… I never changed anything from when I pulled it off. ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: SteveM C/IL

Date Posted: 26 Aug 2025 at 11:05am

| I can't tell from pic. Is head about 4in thick? Should be on a 17. |

Posted By: Les Kerf

Date Posted: 26 Aug 2025 at 11:11pm

The only thing I have heard about regarding two different pedestal heights involves the early WD heads vs the later WD and the WD45 head; i.e. the 'Short' head and the 'Tall' head, which requires different pedestals. According to three different online advertisements selling rocker pedestals for the D17 they measure 1.945" tall.

|

Posted By: TedN

Date Posted: 27 Aug 2025 at 12:38am

Not sure how to do links but I was able to download the picture. Maybe I'm wrong, but it looks different to me. Keep in mind I don't have much familiarity with D17s, I am only going by what I see in the pictures. Ted ------------- 190XTD seriesIII, 190XTD seriesI, maroon belly 7000, 190XTD series??? project(or maybe parts) |

Posted By: Sugarmaker

Date Posted: 27 Aug 2025 at 6:51am

|

Ok guys, I am on the edge of my seat (ok the couch) and the popcorn is almost gone! I need Dr Allis to tell me a little more about valve guide placement. No I am not a engine builder. No I know nothing about valve guides. (I have a machine shop do the head work on any engines I am working on which is not very many) But it sounds like if the guides are incorrectly installed this stops the valve movement and then can bend the pushrods on the other end of the rocker? I am a little confused but I am old and easily confused too. Humm This is like a who dunit murder mystery. Let's all take a trip to 55 Allis land stand around drink coffee or beer and noodle and lay hands on this awesome restoration. Sorry for being sarcastic on the restoration thing. I do a little work every couple years on my own stuff. I make many mistakes. But I do not call any of these old tractor projects "restorations"! That word is for folks that have way more skills than I have. But I must say I was not impressed with the very first exterior picture of this finished restore D17. Sorry maybe my expectations are too high. And yes shiny paint does not mean it will run. I understand that. But if a customer is going to pay good money for 7 years of fiddling the details should be slightly better inside and out. Just my rambling 2 cents. Not trying to step on anyone's toes here. I hope this tractor can be completed for the owner and that they get many years of enjoyment with it. Makes me want to find the old D17 and fire it up! Regards, Chris and Cheryl I just started another batch of popcorn. I like the wrong head or wrong rocker arm combo idea for some reason? :) Maybe the butler did it! I also wish Don Bradley was able to chime in on this engine situation too. RIP Don! Just thought of another one for the team! Could the push rods have been purposely pre bent so that they made the valve train look like it functioned. Ok that idea is stranger than aliens building the pyramids!

------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: Les Kerf

Date Posted: 27 Aug 2025 at 8:28am

It would be interesting to know what the rebuilder has to say about the guides

|

Posted By: 55allis

Date Posted: 27 Aug 2025 at 12:42pm

|

Talked to the shop who has the head and he hasn’t looked at it yet… Said he’d try to look at it today or tomorrow. The valve guides look original, rust is still on the bottom side. So I don’t think it would be that. ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: Les Kerf

Date Posted: 27 Aug 2025 at 2:33pm

I'm beginning to think that way myself

Reckon maybe it was Col. Mustard? Reckon maybe it was Col. Mustard?  |

Posted By: 55allis

Date Posted: 02 Sep 2025 at 11:27am

|

It’s been a week now and I’m still waiting on the head… He did give me an update and found the seats was ground to a 30 degree instead of a 45 degree… so he’s going to grind them again to correct them. Would that be enough to stick the valves? And bend the push rods? Onto the rear crank seal: it does appear to have been replaced BUT in the process it appears he turned a wrench too much and cracked the top seal retainer.  What material is that made of? Is it weldable? It feels like aluminum but it could be cast aluminum. ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: DrAllis

Date Posted: 02 Sep 2025 at 11:34am

| Intake valves on any D-17 head are 30 degrees. Exhaust are 45 degrees. |

Posted By: 55allis

Date Posted: 02 Sep 2025 at 11:55am

Called him and he figured that out before he did anything. Thank Doc ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: Allis dave

Date Posted: 03 Sep 2025 at 7:15am

| There are lots of those crank seal holders around. Call Bill Deppe or Orange Knight(Lad Benes) and see if they have one. |

Posted By: SteveM C/IL

Date Posted: 03 Sep 2025 at 11:55am

| ....and remember to GLUE felt in place. |

Posted By: 55allis

Date Posted: 08 Sep 2025 at 10:05am

What kind of glue has worked best for you? ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: 55allis

Date Posted: 08 Sep 2025 at 11:24pm

|

Well it’s now on the path to come together again!! Got the rear crank seal put in and the fly wheel on, now I’m waiting on the clutch input seals to come in, maybe tomorrow afternoon mail and I need to pick up the head from the head shop. ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: 55allis

Date Posted: 09 Sep 2025 at 11:36pm

|

Good news today!!! Got it to spin over freely and no bending push rods!! Starter spins it nicely, very good compression (finger test) it almost will suck my finger in the spark plug hole!! So far no leaks on the seals I put in.. I think it will fire right up when I can get spark. Gas line was completely plugged with crap so I had to blow air through it until it came out. I adjusted the valves to .015 of an inch cold, so I think that should do until it warms up. ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: 55allis

Date Posted: 10 Sep 2025 at 9:51am

|

Good news once again!! It runs like a champ!! ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: Les Kerf

Date Posted: 10 Sep 2025 at 11:53am

WHEEEEEE!!!  |

Posted By: DrAllis

Date Posted: 10 Sep 2025 at 12:42pm

| Why 8 bent push rods ???????? |

Posted By: ACinSC

Date Posted: 10 Sep 2025 at 1:02pm

| Glad you asked Dr Allis. I was wondering myself. Thanks |

Posted By: 55allis

Date Posted: 10 Sep 2025 at 2:19pm

|

I don’t think previous mechanic knew what he was doing and when he put the rocker on none of the push rods was down in their holes correctly and he ran the bolts down instead of gently pushing it down there for bending all the rods. I just drove it around only to discover a very bad hydraulic leak when lifting. I think this line is the culprit…  I think it is shot… Going to try to find a part number and maybe find a good used one. ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: 55allis

Date Posted: 10 Sep 2025 at 2:25pm

|

Found that line with a part number of 70228425. Than looking at the long line going to the back has job weld patches… That one has a part number of 70229059 ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: Allis dave

Date Posted: 10 Sep 2025 at 4:25pm

|

If you can't find a new or used one, you can make one. I made a lot of new ones for my WD45. You may need to use a little different fittings than original but no one will notice. You could probably go to about any mechanic that does brakes too and have him make and flare you one. |

Posted By: 55allis

Date Posted: 10 Sep 2025 at 8:34pm

|

Are they a double flange? I’m not very good with steel line… I have All States Ag Parts looking for them and they found the long one but was having trouble finding the short one I think it’s was. Maybe Heitman Tractor Salvage would have them? I seen they had a lot of d17s listed on their website. Got to looking at the long one and the other guy tried to jb weld it… Wonder how long that would’ve lasted.. ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: SteveM C/IL

Date Posted: 10 Sep 2025 at 8:58pm

| Inverted flare. A quality tool should form that fine. |

Posted By: 55allis

Date Posted: 11 Sep 2025 at 12:36am

|

What kind of material is best? How thick? I’m pretty sure the original is steel… ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: Allis dave

Date Posted: 11 Sep 2025 at 5:51am

| Use Brake line |

Posted By: 55allis

Date Posted: 16 Sep 2025 at 10:59pm

|

All states ag found some good used ones for me!! I tried some local shops around and they told me they have never seen that big of brake line before… Got them yesterday and put them on, no hydraulic leaks!!!  Had to order front wheel bearings due to one being rusted pretty badly and the other worn out very severely. Should be in tomorrow sometime. I think this project is getting wrapped up now thanks a’ll for the patience and help!!!, ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: plummerscarin

Date Posted: 17 Sep 2025 at 12:18pm

| Is an interesting thread. Thanks for sharing |

Posted By: 55allis

Date Posted: 21 Sep 2025 at 11:00pm

|

Well it got to go home today, hopefully with a happy customer!! ------------- 1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

Posted By: rms61moparman(Ky)

Date Posted: 22 Sep 2025 at 12:57am

|

The owner of that D-17 must have patience and understanding to rival Job!!! In a lot less than 7 years, I'd have been in the supreme court or prison!!! Mike

|

steve(ill) wrote:

steve(ill) wrote: