Front wheel bearing seal

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=205925

Printed Date: 25 Dec 2025 at 1:50pm

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: Front wheel bearing seal

Posted By: AveryD12

Subject: Front wheel bearing seal

Date Posted: 18 Mar 2025 at 12:55pm

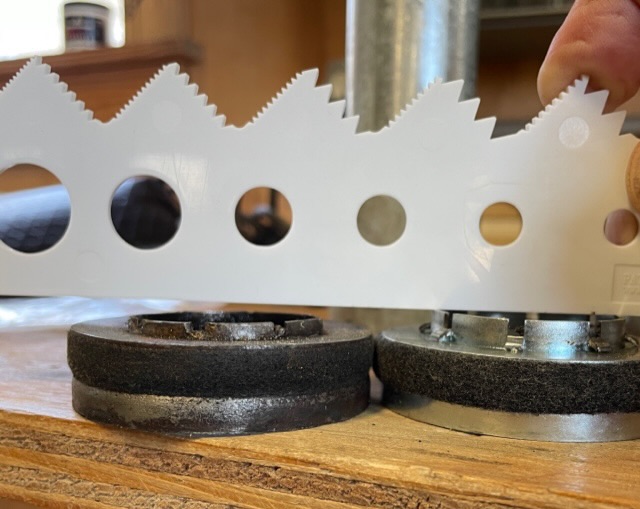

Repacking the front wheel bearings on the D12 series 3. Decided to replace the seals. I never saw a seal like this and I am unsure the proper way to install it. I assume that I should drive it on the spindle and the hub turns against the felt. I’ll try to post a few pictures.

|

Replies:

Posted By: Gary

Date Posted: 18 Mar 2025 at 1:19pm

|

The Allis P/N for that style Seal is 207365. From the Allis Parts Catalog it appears Allis used that Style Seal on Ser. I and Ser. III. From the picture it appears that the Seal installs to the bottom of the front Spindle with the Outer Diameter Seal Portion facing outboard towards the Hub. It appears you would have to press the Seal on to the Spindle. The Seal would remain Stationary and the Hub would turn. Gary |

Posted By: AveryD12

Date Posted: 18 Mar 2025 at 1:28pm

| Thanks. I will need to remove the spindle and carry it to a shop that has a press to get it installed. |

Posted By: Gary

Date Posted: 18 Mar 2025 at 1:39pm

|

Avery I don't think you need to go to that much work. Do you have a set of 3/4" Drive Sockets? Choose a Socket large enough to just fit on the inside below the Seal Material. Add the long 3/4 Drive Extension so that you can keep the Seal square to the Spindle. If you don't have a Set of 3/4 Drive, a piece of pipe a foot or so long would work. Gary ................................................................. Looking closer at the Picture, that Seal may face inboard. Perhaps do a dry run by assembling the Hub and Bearings to the Spindle to be sure. |

Posted By: PaulB

Date Posted: 18 Mar 2025 at 1:42pm

|

I've made a tool which just fits over the spindle and is the proper length to use the nut to draw those seals in place. Be sure to oil the felt real good. ------------- If it was fun to pull in LOW gear, I could have a John Deere. Real pullers don't have speed limits. If you can't make it GO... make it SHINY |

Posted By: Gary

Date Posted: 18 Mar 2025 at 1:47pm

|

Paul Perhaps you could verify for Avery which way the Seal faces. G |

Posted By: PaulB

Date Posted: 18 Mar 2025 at 1:49pm

|

The side with the 1177 mark goes on first. ------------- If it was fun to pull in LOW gear, I could have a John Deere. Real pullers don't have speed limits. If you can't make it GO... make it SHINY |

Posted By: AveryD12

Date Posted: 18 Mar 2025 at 2:04pm

| Thanks for the help |

Posted By: AveryD12

Date Posted: 18 Mar 2025 at 3:50pm

|

Paul Do you have picture of the tool you fabricated for installing this seal? I would be very grateful if you can share it with me. I think I understand the concept but a picture would be most helpful. Thanks |

Posted By: PaulB

Date Posted: 18 Mar 2025 at 7:06pm

|

It's just a piece of pipe that I bored a length inside to fit the spindle and a thick washer under the spindle nut. I've found no other way to get them started straight without bending them now that all of them are made in China or someplace else now. The old NOS ones would tap on easily every time. ------------- If it was fun to pull in LOW gear, I could have a John Deere. Real pullers don't have speed limits. If you can't make it GO... make it SHINY |

Posted By: AveryD12

Date Posted: 18 Mar 2025 at 8:15pm

Ok. Thanks. I believe I can build something like that. I tried a 1-1/2” pipe collar/sleeve and it is slightly smaller than the OD of the seal. I can probably reduce that to a smaller diameter pipe that will be slightly larger than the spindle diameter and cut to length. Thanks again for all your help. I did notice the new seal is thicker in area that goes on the spindle. I suppose the old one is worn from years of use.

|

Posted By: PaulB

Date Posted: 19 Mar 2025 at 6:29am

|

You want the ID of the pipe to just fit onto the spindle. ------------- If it was fun to pull in LOW gear, I could have a John Deere. Real pullers don't have speed limits. If you can't make it GO... make it SHINY |

Posted By: Gary

Date Posted: 19 Mar 2025 at 10:04am

|

Just looked this Seal up on Amazon. $350 CAN G |

Posted By: AveryD12

Date Posted: 19 Mar 2025 at 12:15pm

|

Paul Thanks, I will see what I can come up with. Gary $350….that’s unreal. I gave $20 for this one. |