3pt Arms Need Clocked

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=193356

Printed Date: 17 Dec 2025 at 6:43am

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: 3pt Arms Need Clocked

Posted By: Mosin9130

Subject: 3pt Arms Need Clocked

Date Posted: 07 Feb 2023 at 6:59pm

|

Evening Allis folks! Quick question and some advice needed on my D15 II. Per the pic below, my 3 pt arms are not level. I'm assuming I need to remove one and "clock" it accordingly. Looks like I will need to pull the fender to get some room but what will I need to get the arm off? Any recommendations on type and size of puller? Plan on using heat?  ------------- '56 WD 45...'63 D15 II...'66 D17 IV |

Replies:

Posted By: DiyDave

Date Posted: 07 Feb 2023 at 7:11pm

Looks like the right one is a little high, if they both are at the lowest point of travel. IIRR, the arms are on a splined shaft, with a simple snap ring, on the inside and outside, iou just need the right screw driver or small cold chisel to pry them out, till they slide over the splines... Hard part is, if they have rusted to the splines, you may have to heat and beat to get them to move. Heat then tap inward then outward, once you see movement, you are most of the way there! ------------- Source: Babylon Bee. Sponsored by BRAWNDO, its got what you need! |

Posted By: steve(ill)

Date Posted: 07 Feb 2023 at 7:22pm

|

look close at the splines between the arm and the case... could be assembled wrong, or could have been overloaded and twisted the shaft... are the splines STRAIGHT ? ------------- Like them all, but love the "B"s. |

Posted By: DrAllis

Date Posted: 07 Feb 2023 at 7:23pm

| You'll likely not be able to remove either arm in chassis without damaging them and 3 point hitch parts are very scarce. Have you determined which arm is incorrect ??? That would be first. I think I would remove the lift arm housing and drive out one roll pin and then pull out the shaft/lift arm that you want to change. It can be disassembled from the inside as everything is covered with oil and a slip fit, unlike the outside spline connections. Place the arm/shaft in a press using a bearing splitter or a thick wall piece of pipe and a bearing splitter. Torch heat will probably be needed, but be careful. I hope the shaft isn't twisted, altho the shaft itself should be the same as a snap coupler tractor. |

Posted By: DiyDave

Date Posted: 07 Feb 2023 at 8:33pm

I took a look at the picture, again. I don't see anything twisted. But then again, I am looking at it from some 1400 miles away, through a computer! Look at the right crank, looks newer, possibly that is the one that was assembled wrong. That is where I'd start, hoping that if it was assembled wrong, more recently than the other one! ------------- Source: Babylon Bee. Sponsored by BRAWNDO, its got what you need! |

Posted By: Gatz in NE

Date Posted: 07 Feb 2023 at 8:54pm

|

someone's attempt to “level” a plow? I’d guess the right side has been moved. |

Posted By: 200Tom1

Date Posted: 07 Feb 2023 at 11:25pm

| Heat and a 3 lb hammer took the ones off my 1968 D17 series 4 when I convert it to a factory 3 point. It made a whole new tractor out of it. |

Posted By: MACK

Date Posted: 08 Feb 2023 at 6:16am

| One twisted. One spline moves it alot more than what it is. MACK |

Posted By: AC720Man

Date Posted: 08 Feb 2023 at 9:24am

|

I agree with Dr Allis and Mack. My guess is it is twisted because I had this happen to me when I was a teenager. I backed out of the furrow in hi-reverse with dads heavy Oliver 3 bottom plow, when the left tire went down into the furrow and came back up it was a violent shock and it twisted the shaft inside the rear housing. I had been using low range knowing I needed to be going slow up to that point. We removed the plow in the field when dad got home from work and took it home to remove the rear housing. I can remember us taking it to the dealer and the owner looked at dad and said how and the **** did ya do that? Dad pointed to me and said ask him? I was so embarrassed. I love to plow and that taught me a valuable lesson. ------------- 1968 B-208, 1976 720 (2 of them)Danco brush hog, single bottom plow,52" snow thrower, belly mower,rear tine tiller, rear blade, front blade, 57"sickle bar,1983 917 hydro, 1968 7hp sno-bee, 1968 190XTD |

Posted By: Mosin9130

Date Posted: 08 Feb 2023 at 11:57am

|

You all are awesome, thank you for all the feedback! With that said...NUTS! I was hoping it was a "quick fix" requiring just a minor adjustment but now it potentially being twisted has me wondering/worried. The tractor is 4 hrs away on my farm and it will be a couple of weekends till I get there to work with it. I'll get some more pics for you all to help analyze but in the meantime I'll plan for the worse. I've only recently acquired the tractor so not sure what happened previously to create this situation. At the end of the day, this is a hobby tractor for a hobby farm. Plan was to utilize this tractor for brush hogging and misc chores. This tractor also helped me round out my "D" collection (D10/D15/D17/D19) and with a recent engine rebuild and freshening up, I'm not wanting to give up on it. ------------- '56 WD 45...'63 D15 II...'66 D17 IV |

Posted By: JC-WI

Date Posted: 08 Feb 2023 at 12:26pm

|

Guess you could still use it the way it is, just shorten the low side or extend the high side to level. Have one D17 that somebody set the lift arms up one spline, raises everything up higher for sure. Don't remember it causing any problems set that way. Just looked at a D14 book and shows the lift shafts are 2 piece and pinned inside so they are not able to be one spline off. So, it is either one arm set one spline off outside the housing, or the shaft twisted. So then comes the question, which shaft? Good Luck ------------- He who says there is no evil has already deceived himself The truth is the truth, sugar coated or not. Trawler II says, "Remember that." |

Posted By: Les Kerf

Date Posted: 08 Feb 2023 at 9:01pm

If it is indeed twisted, what are the odds that it is still perfectly straight? I would raise and lower it while closely observing the end of the shafts to see if one of them wobbles. That would be the twisted sister (I think)  |

Posted By: AC720Man

Date Posted: 08 Feb 2023 at 10:01pm

|

Safest way to find out is to remove the rear housing to be sure. ------------- 1968 B-208, 1976 720 (2 of them)Danco brush hog, single bottom plow,52" snow thrower, belly mower,rear tine tiller, rear blade, front blade, 57"sickle bar,1983 917 hydro, 1968 7hp sno-bee, 1968 190XTD |

Posted By: Mikez

Date Posted: 08 Feb 2023 at 10:13pm

|

Just to throw another thought in the ring. Looks like the threaded parts had been heated up. Maybe the person couldn’t get them to turn and moved the arm on splines for plowing. Not saying I believe it lol just a thought

|

Posted By: AC720Man

Date Posted: 08 Feb 2023 at 10:26pm

|

Mike that is a possibility, there should be visible evidence of one of those arms being removed and put back on unless it was changed inside the housing. It is a 2 piece shaft. It would have been much easier to remove the adjusters and put new or good used adjusters on. ------------- 1968 B-208, 1976 720 (2 of them)Danco brush hog, single bottom plow,52" snow thrower, belly mower,rear tine tiller, rear blade, front blade, 57"sickle bar,1983 917 hydro, 1968 7hp sno-bee, 1968 190XTD |

Posted By: jaybmiller

Date Posted: 09 Feb 2023 at 6:33am

|

I'm thinking the right one has to be 'reclocked',as the left is the lowest one. Before removing the HEAVY,AWKWARD section of 'rockshaft', I suggest trying to push the arm off by installing a series of 'wedges' between the arm and the casing. I'd hate to read that you whacked the arm once too hard and broke it. Sad thing is I have a 'long armed slap hammer puller' here that might actually get the arm off I've done the 'wedge from behind' on PITA small engine crankshaft pulleys that have 'magically, rust welded' onto the 1" crankshaft. for sure clean the 'exit side' of the splines real good,get RID of ALL paint and crud in the grooves,maybe file them done a bit ,'dress'. The more tools you take the better !Odds are if you take 90% of your garage up there, the arm will come off in the first 5 minutes....leaving you wondering 'WHY, did I bring all this stuff ? ' ------------- 3 D-14s,A-C forklift, B-112 Kubota BX23S lil' TOOT( The Other Orange Tractor) Never burn your bridges, unless you can walk on water |

Posted By: DrAllis

Date Posted: 09 Feb 2023 at 7:25am

| If one of the shafts is twisted, it would likely be the one that is the lowest. What are the odds of twisting one upwards ??? |

Posted By: Tbone95

Date Posted: 09 Feb 2023 at 7:38am

| Ya, I don't know how you would twist one up. About the only way would be to hit it with another tractor or back into something juuuuuuuuussst right. Doesn't seem to likely! |

Posted By: Dennis J OPKs

Date Posted: 09 Feb 2023 at 8:26am

| Other than the appearance from a looks standpoint driving you nuts. If it will do what you need it to do by adjusting arm length, you might want to think twice about a fix. Just a thought, the older I get, the lazier I seem to become. |

Posted By: JoeO(CMO)

Date Posted: 09 Feb 2023 at 8:32am

|

Drain oil. Remove PTO shaft. Inspect shafts for twisting. Inspect ram coupler for damage. That difference is less than one spline. |

Posted By: jaybmiller

Date Posted: 09 Feb 2023 at 8:33am

|

dang, I need to see which shaft IS twisted !! even though there's adjustable arms, won't it lift 'funny' as the ends of the arms are at different 'clocks' ? One of those 'gotta see it ,to understand' things.... BTW wife says you can have a rockshaft off one of my D-14s, if you take the WHOLE tractor..... ------------- 3 D-14s,A-C forklift, B-112 Kubota BX23S lil' TOOT( The Other Orange Tractor) Never burn your bridges, unless you can walk on water |

Posted By: Mosin9130

Date Posted: 09 Feb 2023 at 2:28pm

|

This has been quite the discussion and boy am I learning from you all...much appreciated! I looked through my photos and happened to find this one which shows the arms from another angle. They don't look like they have been touched before. I did remove the adjusters and brought those back home with me to clean them up as they wouldn't turn very well. They work great now so when I'm back up, I can put them on and try to adjust accordingly.  ------------- '56 WD 45...'63 D15 II...'66 D17 IV |

Posted By: DrAllis

Date Posted: 09 Feb 2023 at 3:04pm

| The left lift shaft is longer than the right lift shaft, so it would be more likely to twist than the shorter one. Just so happens the left side is lower............hmmmm..... |

Posted By: Stan R

Date Posted: 09 Feb 2023 at 3:25pm

| LIFT Shaft replaced with a different series tractor whereby the splines are not cut to the same orientation?? |

Posted By: AC720Man

Date Posted: 09 Feb 2023 at 4:40pm

. .------------- 1968 B-208, 1976 720 (2 of them)Danco brush hog, single bottom plow,52" snow thrower, belly mower,rear tine tiller, rear blade, front blade, 57"sickle bar,1983 917 hydro, 1968 7hp sno-bee, 1968 190XTD |

Posted By: AC720Man

Date Posted: 09 Feb 2023 at 4:43pm

|

Curious, I measured dad’s series II D15 from the floor to the center of the bolt of each arm. The left side is 1” shorter than the right if the paved driveway is level where I measured it from. There is some obvious wear at the knuckles so it may be less. ------------- 1968 B-208, 1976 720 (2 of them)Danco brush hog, single bottom plow,52" snow thrower, belly mower,rear tine tiller, rear blade, front blade, 57"sickle bar,1983 917 hydro, 1968 7hp sno-bee, 1968 190XTD |

Posted By: AC720Man

Date Posted: 09 Feb 2023 at 4:49pm

|

I recall it took a press to remove the shaft from the lift arm when the dealership replaced dad’s. ------------- 1968 B-208, 1976 720 (2 of them)Danco brush hog, single bottom plow,52" snow thrower, belly mower,rear tine tiller, rear blade, front blade, 57"sickle bar,1983 917 hydro, 1968 7hp sno-bee, 1968 190XTD |

Posted By: Gatz in NE

Date Posted: 09 Feb 2023 at 5:45pm

|

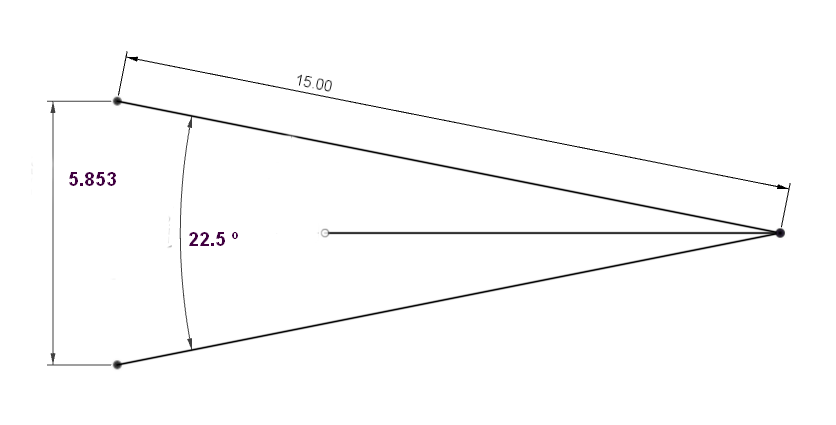

The LEFT (p/n 70227791) and RIGHT (p/n 70227792) are the same for D14s and D15s. They are different lengths due to the Crank being offset to clear the ring gear. Each shaft is drilled for a roll-pin; as is the Crank to match. It appears from the shaft drawings that there are 15 or 16 splines on both ends. For production purposes, these would all be clocked the same; otherwise there would be a never ending problem. If at 16 deg, one spline would change the "clocking" by 22.5 deg That's a lot of movement at the end of the lift arm. The OP could measure his tractor's lift assembly as did AC720Man to see if the difference is that great. If someone knows the exact count of splines and the distance from the center of a lift shaft to the center of the bolt that AC720Man is referring to, we can calculate what a one-spline index change would make.

|

Posted By: steve(ill)

Date Posted: 09 Feb 2023 at 9:16pm

|

your right Dwight.... the SIN of 23 degree is .37 ...... so lets assume the arm in 15- 16 inches long...... that means when you move the arm 1 NOTCH... you move the pin between 5 and 6 inches .............. his photo looks more like 2 inches... so it is TWISTED. ------------- Like them all, but love the "B"s. |

Posted By: Gatz in NE

Date Posted: 10 Feb 2023 at 10:36pm

|

This view makes it look not nearly as bad as the first picture posted.  One thing the OP could do is use a carpenter's square and straight piece of something to check the height of the arms. Check from both directions. Another thought..... if the broached splines on the arms are not clocked the same, that might cause the difference. But again, this would not likely be the case in production.

|

Posted By: JC-WI

Date Posted: 11 Feb 2023 at 12:04am

|

Looks like the arm has been whacked on the upper corner inside part of right lift arm. Wonder if spline orientation is the same from the left side to the right side...? ------------- He who says there is no evil has already deceived himself The truth is the truth, sugar coated or not. Trawler II says, "Remember that." |

Posted By: Phil48ACWC

Date Posted: 11 Feb 2023 at 8:53am

|

https://www.ebay.com/itm/394076824050?hash=item5bc0cf21f2:g:og0AAOSw8rtigb-Y&amdata=enc%3AAQAHAAAAsPK%2BI%2B4pygS34nqeBsNqQ2hv%2F6ET1vxvD5e0Ns90UdUTWT5fO2LAisq5gvW6OvotxGnstiKKxkMlDp5VxEmXEmNgzgsjpDe00t58%2FAO6%2BmpKLzqnU%2BDwwUUmmrrIw5qXf9XZRKgB2zkKF9jJ7CyUTh0uXpuXeejgLu3BLmwIH5f9ZE%2B1sm3qMkgm9D7jyOx%2BhBSp6IaiMdoYYd60jin7ypJl9INje4liUA9rdcFFNh8o%7Ctkp%3ABk9SR-KXgY_IYQ%20" rel="nofollow - https://www.ebay.com/itm/394076824050?hash=item5bc0cf21f2:g:og0AAOSw8rtigb-Y&amdata=enc%3AAQAHAAAAsPK%2BI%2B4pygS34nqeBsNqQ2hv%2F6ET1vxvD5e0Ns90UdUTWT5fO2LAisq5gvW6OvotxGnstiKKxkMlDp5VxEmXEmNgzgsjpDe00t58%2FAO6%2BmpKLzqnU%2BDwwUUmmrrIw5qXf9XZRKgB2zkKF9jJ7CyUTh0uXpuXeejgLu3BLmwIH5f9ZE%2B1sm3qMkgm9D7jyOx%2BhBSp6IaiMdoYYd60jin7ypJl9INje4liUA9rdcFFNh8o%7Ctkp%3ABk9SR-KXgY_IYQ

You can remove fender and use a large puller like above to remove arm. This style puller can be set up as a 2 or 3 jaw. Clean up internal and external splines good with a wire brush and reassemble with anti-seize compound. I agree with steve(ill). Looks like 16 spline shaft = 22.5 degrees per spline. If you move the arm one spline and the arm is 15" -16" long, the end of the arm would move 5-6". Way too much to fix your issue. So something has to be bent or twisted. I would crank on the lift adjustments to dial it in and avoid disassembly and opening a bag of snakes.

|

Posted By: Gary

Date Posted: 11 Feb 2023 at 10:29am

|

To KEEP IT SIMPLE S how about removing the left hand crank and adding a stack of flat washers ( an inch plus ) to raise the Crank and be a closer match to the right hand crank. G |

Posted By: Fred in Pa

Date Posted: 11 Feb 2023 at 10:49am

|

Why not just pull housing off and check shafts. Then u can also replace cylinder packing and hyd. hose while in there . Then u can press the shaft out of the arm with out damage to arm. ------------- He who dies with the most toys is, nonetheless ,still dead. If all else fails ,Read all that is PRINTED. |

Posted By: AC720Man

Date Posted: 11 Feb 2023 at 12:39pm

|

If you have plans of using the 3 point for anything the housing needs to come off to see what needs to be repaired. It’s not that difficult of a job. Continuing to use it with a bush hog or other heavy equipment could result in further damage. Get a service manual and you can see how it comes apart. ------------- 1968 B-208, 1976 720 (2 of them)Danco brush hog, single bottom plow,52" snow thrower, belly mower,rear tine tiller, rear blade, front blade, 57"sickle bar,1983 917 hydro, 1968 7hp sno-bee, 1968 190XTD |

Posted By: steve(ill)

Date Posted: 11 Feb 2023 at 12:52pm

|

location is part of the problem...... The tractor is 4 hrs away on my farm and it will be a couple of weekends till I get there to work with it. I've only recently acquired the tractor so not sure what happened previously to create this situation. At the end of the day, this is a hobby tractor for a hobby farm. Plan was to utilize this tractor for brush hogging and misc chores. ------------- Like them all, but love the "B"s. |

Posted By: Gatz in NE

Date Posted: 11 Feb 2023 at 2:49pm

|

Is there someone at or near you farm that could try and lift up the RT arm? Other than the RT shaft having been twisted as a lot have suggested; and although not likely, if there's a great deal of free movement, it may have even sheared. Revisiting the 1-spline index; this would be too much of a distance on the end of a 15" arm when moved one spline, compared to the picture.  |

Posted By: AC720Man

Date Posted: 11 Feb 2023 at 9:55pm

|

When I twisted dad’s left shaft it didn’t break in 2, it twisted and dropped the left side. No damage was done to the rear housing. When I heard it thankfully I dropped the plow immediately. It was too late but it may have prevented further damage. ------------- 1968 B-208, 1976 720 (2 of them)Danco brush hog, single bottom plow,52" snow thrower, belly mower,rear tine tiller, rear blade, front blade, 57"sickle bar,1983 917 hydro, 1968 7hp sno-bee, 1968 190XTD |

Posted By: jaybmiller

Date Posted: 12 Feb 2023 at 6:42am

|

I tried counting the splines on my D-14, SC arms...15 or 16 ( fender is IN the way,kept losing count.....). Tried Google, a few pictures,but no GREAT shot of the end. Still either 15 or 16 won't make a big difference to Gatz' drawing and numbers. Sure hate to think of the force that did twist the shaft though !!! Honestly, I'd put the tractor on a trailer and bring her home to SAFELY work on it. There is NO way I'd TRY to remove the rockshaft off without some kind of crane. Did mine, in my garaeg with overhead Ibeam, chain hoists,lotsa light, tools and it was 'ok',AFTER I dumped the diff oil into a 5G bucket....yeah that SHOULD have been 'step 1'..... While it's home,reseal the ram and add a swivelled hose while it's apart ! ------------- 3 D-14s,A-C forklift, B-112 Kubota BX23S lil' TOOT( The Other Orange Tractor) Never burn your bridges, unless you can walk on water |

Posted By: Mosin9130

Date Posted: 12 Feb 2023 at 3:54pm

|

Thank you everyone for the help! You all have helped me realize that 1) I have an issue that most likely is a twisted shaft and that 2) I need to take the time and consideration that this won't be an easy job where the tractor sits 4 hrs from here. Without my shop built yet, my plan is to trailer the tractor down to my Dallas residence and properly delve into getting this resolved. As others have mentioned, I can probably "live" with this for awhile so it may be Summer till I get it down (wrapping up a Land Cruiser restoration so my extra garage space is currently utilized). With that said, I did just purchase another D15 II that will be ready to "hit the ground running" so that helps buy some time as well. I did have to explain to the wife that I "needed" another D15 II though in the meantime.  ------------- '56 WD 45...'63 D15 II...'66 D17 IV |

Posted By: AC720Man

Date Posted: 12 Feb 2023 at 5:28pm

|

A good choice, it’s a really good tractor for its size. Does well with a bush hog on it ------------- 1968 B-208, 1976 720 (2 of them)Danco brush hog, single bottom plow,52" snow thrower, belly mower,rear tine tiller, rear blade, front blade, 57"sickle bar,1983 917 hydro, 1968 7hp sno-bee, 1968 190XTD |

Posted By: DiyDave

Date Posted: 12 Feb 2023 at 5:31pm

Hell, My theory is is that you need another AC tractor, for every attachment you own. That way you won't injure yourself transferring 3 point equipment, from 1 machine, to the ground, to another. Note, this does not apply to snap coupler equipment, because you don't get injured hooking SC equipment up! ------------- Source: Babylon Bee. Sponsored by BRAWNDO, its got what you need! |

JC-WI wrote:

JC-WI wrote: