Need help with Model G engine, carb, maybe more

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=139254

Printed Date: 23 Oct 2025 at 12:24am

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: Need help with Model G engine, carb, maybe more

Posted By: sawjinc

Subject: Need help with Model G engine, carb, maybe more

Date Posted: 09 Jun 2017 at 8:33pm

|

Hey everyone. I've recently fully rebuilt the engine for my G, and I've yet to get it to start. New rings, valves, gaskets, ignition, etc. First - anyone have good instructions on rebuilding the TSV13 carb? I cannot tell where the orings go on the main jet Second - what readings should I be getting for compression? I have compression on all 4, just not sure if it's enough Third - any tips for my situation? Thanks Steve |

Replies:

Posted By: Gerald J.

Date Posted: 09 Jun 2017 at 9:13pm

|

I have owner's and shop manual for the G on line at: http://www.geraldj.networkiowa.com/Trees/" rel="nofollow - http://www.geraldj.networkiowa.com/Trees/ Gerald J. |

Posted By: Dick L

Date Posted: 09 Jun 2017 at 9:14pm

|

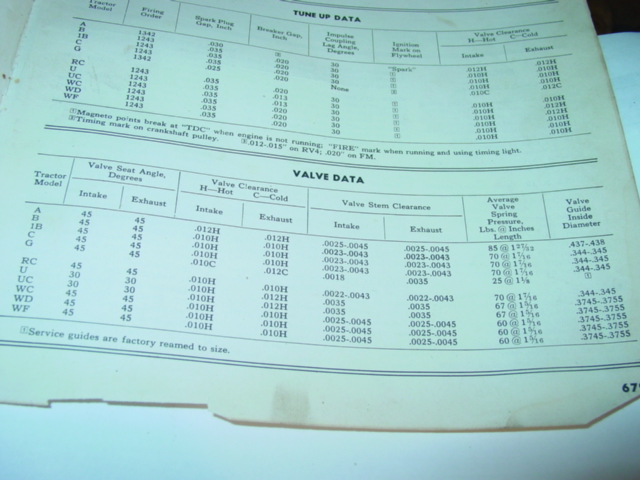

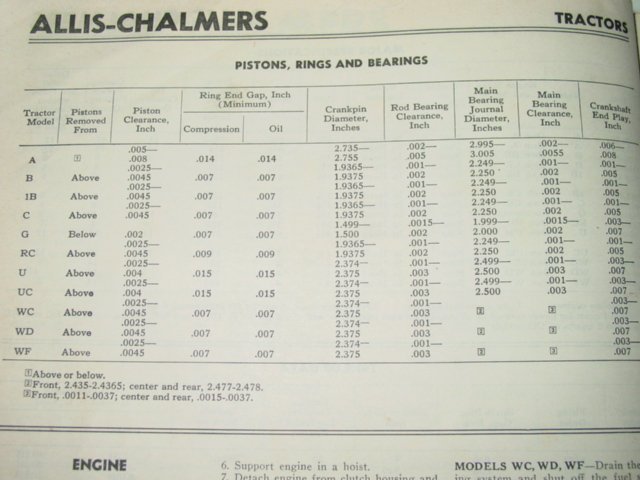

The O ring would be a hard flat washer that slips over the threads of the jet before it is screwed in. What was the ring gap down in the cylinder before you placed the rings on the pistons? What is the valve lash? Firing order is 1-3-4-2 on the G. Some info:

|

Posted By: sawjinc

Date Posted: 09 Jun 2017 at 9:34pm

|

Thank you both. for the main jet, I was referring to the two items circled in the image below. I unfortunately did not measure gap before closing it up. the engine is bored .030 over and I ordered rings for .030 over. The valves were all set to 18/35, though at this point I am tempted to recheck all of them. |

Posted By: Dick L

Date Posted: 10 Jun 2017 at 7:37am

|

Valve clearance is (.010 for intake and .012 for exhaust) The stem clearance in the chart means side clearance inside the guide and is not .018 but .0018 as the tightest fit (minimum) that is almost .002. with the (maximum) loosest fit being .0035 being less than .004. When the clearance gets to .004 or over the only fix is to put in new guides. Yes you should reset the valve clearance between the end of the valve and the lifter. Setting the exhaust valve to .035 would not give the proper opening to remove the exhaust with ease. when working in thousands those pesky zeros mean a world of difference. |

Posted By: sawjinc

Date Posted: 10 Jun 2017 at 7:48am

| Ok thanks I'll go check them and reset |

Posted By: Dick L

Date Posted: 10 Jun 2017 at 8:23am

I set the valve to lifter to a easy slide with the feeler gauge not a tight pull slide. This is slightly over the feeler gauge thickness which is fine. |

Posted By: Dick L

Date Posted: 10 Jun 2017 at 8:26am

| Also remember that the number one plug is close to the timing gear at the rear of the tractor when running the plug wires. 1-3-4-2 |

sawjinc wrote:

sawjinc wrote: