WD45 Dipstick?

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=133187

Printed Date: 22 Dec 2025 at 11:33am

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: WD45 Dipstick?

Posted By: 79fordblake

Subject: WD45 Dipstick?

Date Posted: 29 Dec 2016 at 9:09pm

| Anybody have trouble with their dipstick fitting after putting in a D17 oil pump converting over to full flow oiling? I had to bend the dipstick to go around the oil pump pickup. With 6 quarts in the pan it's reading at the first line below full. |

Replies:

Posted By: Don(MO)

Date Posted: 29 Dec 2016 at 11:15pm

|

I have not ran into that, all WD/WD45 gas and all D17 gas tractors used the same dipstick AGCO's part # 70230066so it might be the pickup sump that's the trouble. If the engine has the pan on it I'd go ahead bend the dip stick to just clear the pick-up sump and fill the engine with five qt's of oil and make a new mark on the stick then put one more qt in and make a new mark at the new oil full level, if you don't have the pan on then look the pick-up sump over again. ------------- 3 WD45's with power steering,G,D15 fork lift,D19, W-Speed Patrol, "A" Gleaner with a 330 corn head,"66" combine,roto-baler, and lots of Snap Coupler implements to make them work for their keep. |

Posted By: 79fordblake

Date Posted: 30 Dec 2016 at 8:12am

| Don engine is already together up and running. It sounds great with the Nelson muffer. I took a pic of the dipstick hitting sump before I put pan on. I'll get it posted on here in a little bit. |

Posted By: 79fordblake

Date Posted: 30 Dec 2016 at 8:33am

Forgot to say in first post. The dipstick would not clear the crankshaft either!

|

Posted By: Don(MO)

Date Posted: 30 Dec 2016 at 9:12am

Here's one for you to look at, might help. ------------- 3 WD45's with power steering,G,D15 fork lift,D19, W-Speed Patrol, "A" Gleaner with a 330 corn head,"66" combine,roto-baler, and lots of Snap Coupler implements to make them work for their keep. |

Posted By: Stan IL&TN

Date Posted: 30 Dec 2016 at 1:14pm

|

You can grind the old marks off pretty easily and then do as Don said and make new ones. I used a hack saw to make mine. ------------- 1957 WD45 dad's first AC 1968 one-seventy 1956 F40 Ferguson |

Posted By: Bill_MN

Date Posted: 01 Jan 2017 at 6:30pm

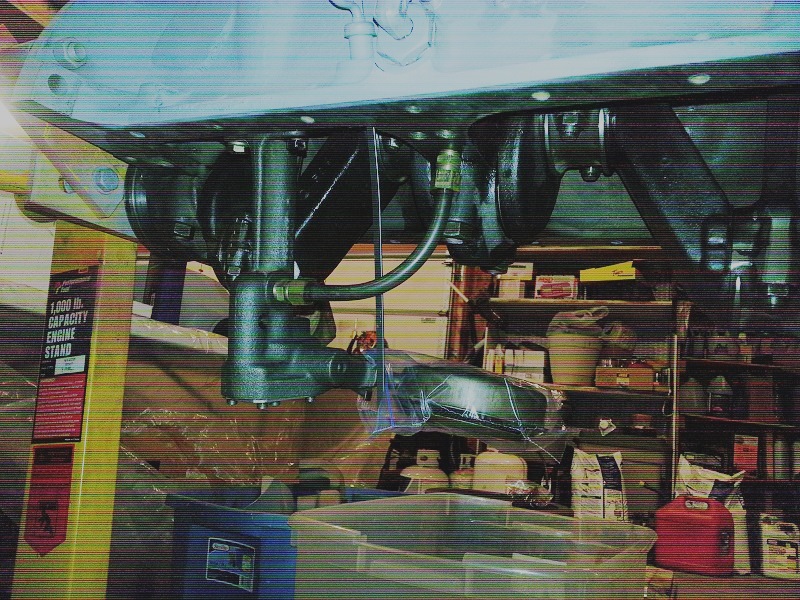

Here's a WD converted to full flow, I did not have to do anything and it fits fine. From the looks of your photo it's bent in toward the middle too far, it should go straight in from the hole then gradually bend back toward the side of the pan after clearing the outlet line. Just bend it back a little bit, no need to change marks if it fits it's right. Sorry about the bag in the way but there is a gap there.  ------------- 1951 WD #78283, 1918 Case 28x50 Thresher #76738, Case Centennial B 2x16 Plow |

Posted By: 79fordblake

Date Posted: 01 Jan 2017 at 7:24pm

| Ill get a pic of what I did to it. I had to bend it quite a bit. It was straight before I messed with it and was hitting oil pickup and crankshaft. The dipstick in the engine I took out is completley straight and doesn't hit anything. |

Posted By: 79fordblake

Date Posted: 02 Jan 2017 at 5:10pm

|

Posted By: Allis dave

Date Posted: 04 Jan 2017 at 7:47am

|

I should've tried putting in my dipstick before I put on the pan... I was over working last night a little and my dipstick went in fine. What I didn't try was to rotate the crank to see if it would hit. It never did before, so I don't know why it would now. Care to share a picture of how you ran your external oil lines sometime? |

Posted By: 79fordblake

Date Posted: 05 Jan 2017 at 3:59am

|

Posted By: Allis dave

Date Posted: 05 Jan 2017 at 7:19am

| That looks right Pretty Blake |

Posted By: Ted J

Date Posted: 05 Jan 2017 at 4:44pm

Some guys just got the knack! NICE WORK!!  ------------- "Allis-Express" 19?? WC / 1941 C / 1952 CA / 1956 WD45 / 1957 WD45 / 1958 D-17 |

Posted By: Don(MO)

Date Posted: 05 Jan 2017 at 5:58pm

On the dip stick look at the diff of the left one and the right one, one thing wrong with the oil level reading off is the stop cap on the right one is moving up and down the shaft needs to be tack welded after you straighten it back, left one is a WD45 or it's a replacement for WC/WD/WD45 the right one is out of a WD or later WC. Have you found the diff, the short part of the two sticks they are opposite. I'd just use the left one and toss the right one away. lol ------------- 3 WD45's with power steering,G,D15 fork lift,D19, W-Speed Patrol, "A" Gleaner with a 330 corn head,"66" combine,roto-baler, and lots of Snap Coupler implements to make them work for their keep. |

Posted By: 79fordblake

Date Posted: 06 Jan 2017 at 12:25pm

| Thanks! It sounds great to. It's only ran for maybe an hour. Now the weather is bad. The left one doesnt work either without bending it. The left one belongs to the engine that came out of the tractor. I would like to keep it with it because I may overhaul it later and stick it in something. I'll Polly buy another dipstick. Yeah Don I knew that one piece was messed up. Not sure why somebody did that to it. I gotta see if I can get some heat going in the shed and tinker around this weekend. I still have to tape up everything and paint the block. But I gotta put up some more tarps in the shed to try to hold in heat. |

79fordblake wrote:

79fordblake wrote: