Slight electrical issue with our B... Need help

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=125510

Printed Date: 14 Aug 2025 at 9:34am

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: Slight electrical issue with our B... Need help

Posted By: Syslogv4

Subject: Slight electrical issue with our B... Need help

Date Posted: 06 Jul 2016 at 6:00pm

I've got a 52 B with a 12v alternator. The tractor would randomly cut off and not start again so I changed the coil. That didn't fix it so I started looking at the wires and saw tons of bare copper. I want to rewire it as simply as possible. No headlights, etc. What gauge wire do I need to run to the alternator and how do I get it all back together? My ammeter has never worked either.

|

Replies:

Posted By: CTuckerNWIL

Date Posted: 06 Jul 2016 at 6:58pm

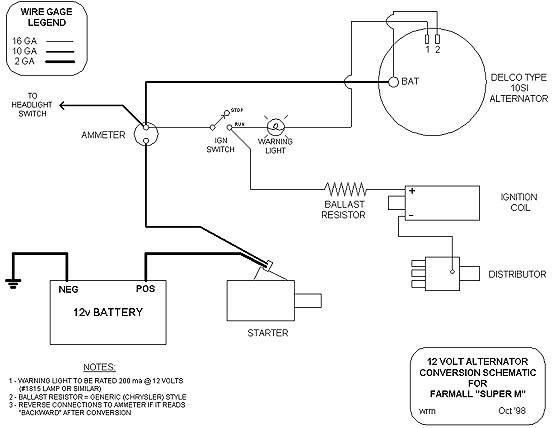

How to wire it, depends on the alternator you have. This would be best to delete the resister and use a 3 ohm 12 volt coil. It also gives a recommended wire size. The warning light can be replaced by a diode but I don't know what diode. ------------- http://www.ae-ta.com" rel="nofollow - http://www.ae-ta.com Lena 1935 WC12xxx, Willie 1951 CA6xx Dad bought new, 1954WD45 PS, 1960 D17 NF |

Posted By: Scott B

Date Posted: 06 Jul 2016 at 7:35pm

|

Connect with Steve in New Jersey and B&B Circuits.com. He has helped me more than once and has all the parts you'll need on his website....including a one wire harness that connects to the alternator. ------------- D17 Series 1 Allis B- 1939 Allis B- 1945 |

Posted By: Gerald J.

Date Posted: 06 Jul 2016 at 9:00pm

|

You need at least 8 gauge for a 50 amp alternator, preferable 6 gauge. The original generator wire can't stand the heat from the alternator current and has melted the insulation. The power wire from the alternator (presume negative ground as positive ground alternators are uncommon) goes to the + terminal on the new 60-0-60 ammeter. Another piece of the same large gauge wire goes from the negative terminal on the ammeter to the battery positive probably at the starter switch connection to the battery. Then to excite the alternator without spinning it fast, you will want a wire from the ignition circuit to the proper connector on the alternator with an indicator lamp, a resistor, or a diode to keep that circuit from backfeeding the ignition circuit and preventing it shutting down by merely opening the ignition switch. Providing you have a distributor ignition not a magneto. That's not a problem with the magneto but you need a switch to apply initial power to the alternator. It could be a momentary push button or a switch (not grounded) that was closed by rising oil pressure. I know NAPA has such a switch. Gerald J. |

Posted By: Syslogv4

Date Posted: 07 Jul 2016 at 6:50am

| I only pulled one wire off of the alternator, so I guess that I have a single wire model. |

Posted By: jaybmiller

Date Posted: 07 Jul 2016 at 7:20am

|

step 1) remove 100% ,yes ALL, of the original wiring step 2) buy a harness from Steve at B&B and install step 3) have fun for the next 50 years and NOT have wiring 'issues'! Now you can wire it yourself but by the time you get the proper wire,connectors, 2-3 pots of coffee and all the TIME spent redoing this end or that end you'll actually SAVE coins by going to Steve. I've rewired 3 of my 4 D-14s and it's an all day job to do it right. Not a lot of wires but weaving them in and out, checking lengths, oops, too short, cut anothter,dang STILL too short....well, you get what does happen. Life is too short. Jay ------------- 3 D-14s,A-C forklift, B-112 Kubota BX23S lil' TOOT( The Other Orange Tractor) Never burn your bridges, unless you can walk on water |

Posted By: BenGiBoy

Date Posted: 07 Jul 2016 at 7:23am

|

The single wire alternators are the easiest to wire, just run one wire from it to the ammeter, then run a wire off of the other side of the ammeter to the battery. (+ side) Not sure on the wire gauge you need, but bigger is better! (I have never done that, but that is how it was explained to me, so I hope it is correct.) HTH, Ben ------------- '39 Model B Tractors are cheaper than girls, remember that! |

Posted By: BenGiBoy

Date Posted: 07 Jul 2016 at 7:24am

|

You might need to do some other wiring because you have a distributor...... ------------- '39 Model B Tractors are cheaper than girls, remember that! |

Posted By: DougS

Date Posted: 07 Jul 2016 at 7:55am

|

Go with #10 wire from the alternator, as Steve's kit would have. Why? Because #10 will self-limit the current going to the battery. As the current goes up, the voltage drop increases, limiting the amount of current. Why do you want to do this? Because if you really dig into battery specs you'll find that you should not charge a battery at a rate faster than 20% of the battery capacity. A 100 AH battery (a big automotive battery, btw) should be limited to 20 AMPS of charge. Unless you plan on using electrical implements that need more power, #10 is more than sufficient. Look beyond the fact that your alternator can provide 60 AMPS, therefor you need #6 wire to accommodate this. How do I know this? Because in my work I used battery banks costing well into the 5-figure amount. My shop did what we needed to do to get the maximum amount of years from our batteries. We looked beyond the surface and followed the battery manufacturer's recommendations to a tee. |

Posted By: Gerald J.

Date Posted: 07 Jul 2016 at 9:22am

|

If you use a 10 gauge wire on a 60 amp 10SI you need to use silicone insulated wire because PVC insulation won't handle the high operating temperature from the current even when limited by the wire resistance. That's what I did with my 4020 and the wire size definitely limits the peak charging with the one wire alternator with the voltage sense terminal connected directly to the output post of the alternator. The charging current would be greater (and so faster) if the voltage sense terminal of the 1 wire alternator was connected near the battery to compensate for the voltage crop in the power wire, but then that power wire will need a NEC current rating equal to that of the alternator, like 50 or 60 amps to keep it from overheating. Its likely to be close to the hot engine block which also tends to melt low temperature wire insulation. The worst place is near the exhaust manifold. Silicone fiberglass wire is a good option. Gerald J. |

Posted By: Steve in NJ

Date Posted: 07 Jul 2016 at 10:07pm

|

Leave one wire Alternators to Hotrods and Muscle cars. They don't belong on a Tractor. If you go to our website, there is a lot of great information on converting to a 12V wiring system the SAFE & easy way. A three wire Alternator isn't that tough to wire up, and its a lot less aggaivation to! Read to articles and you'll understand how things work. I can also build you a simple conversion system without the accessories if your interested. As always, Thank You guys for your referrals to use us. Its greatly appreciated always!! Steve@B&B ------------- 39'RC, 43'WC, 48'B, 49'G, 50'WF, 65 Big 10, 67'B-110, 75'716H, 2-620's, & a Motorhead wife |