| Author |

Topic Search Topic Search  Topic Options Topic Options

|

JC-WI

Orange Level Access

Joined: 11 Sep 2009

Location: wisconsin

Points: 33628

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Feb 2023 at 12:04am Posted: 11 Feb 2023 at 12:04am |

Looks like the arm has been whacked on the upper corner inside part of right lift arm. Wonder if spline orientation is the same from the left side to the right side...?

|

|

He who says there is no evil has already deceived himself

The truth is the truth, sugar coated or not. Trawler II says, "Remember that."

|

|

|

Sponsored Links

|

|

|

Phil48ACWC

Silver Level

Joined: 17 Jan 2013

Location: Vermont

Points: 278

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Feb 2023 at 8:53am Posted: 11 Feb 2023 at 8:53am |

https://www.ebay.com/itm/394076824050?hash=item5bc0cf21f2:g:og0AAOSw8rtigb-Y&amdata=enc%3AAQAHAAAAsPK%2BI%2B4pygS34nqeBsNqQ2hv%2F6ET1vxvD5e0Ns90UdUTWT5fO2LAisq5gvW6OvotxGnstiKKxkMlDp5VxEmXEmNgzgsjpDe00t58%2FAO6%2BmpKLzqnU%2BDwwUUmmrrIw5qXf9XZRKgB2zkKF9jJ7CyUTh0uXpuXeejgLu3BLmwIH5f9ZE%2B1sm3qMkgm9D7jyOx%2BhBSp6IaiMdoYYd60jin7ypJl9INje4liUA9rdcFFNh8o%7Ctkp%3ABk9SR-KXgY_IYQ

You can remove fender and use a large puller like above to remove arm. This style puller can be set up as a 2 or 3 jaw. Clean up internal and external splines good with a wire brush and reassemble with anti-seize compound.

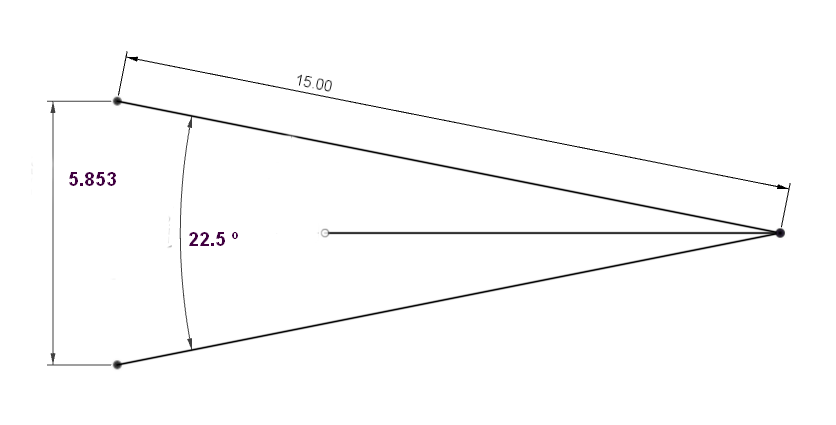

I agree with steve(ill). Looks like 16 spline shaft = 22.5 degrees per spline. If you move the arm one spline and the arm is 15" -16" long, the end of the arm would move 5-6". Way too much to fix your issue. So something has to be bent or twisted. I would crank on the lift adjustments to dial it in and avoid disassembly and opening a bag of snakes.

Edited by Phil48ACWC - 11 Feb 2023 at 9:23am

|

|

Gary

Orange Level Access

Joined: 13 Sep 2009

Location: Peterborough,On

Points: 5170

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Feb 2023 at 10:29am Posted: 11 Feb 2023 at 10:29am |

|

To KEEP IT SIMPLE S how about removing the left hand crank and adding a stack of flat washers ( an inch plus ) to raise the Crank and be a closer match to the right hand crank.

G

|

|

Fred in Pa

Orange Level

Joined: 13 Sep 2009

Location: Hanover Pa.

Points: 9100

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Feb 2023 at 10:49am Posted: 11 Feb 2023 at 10:49am |

|

Why not just pull housing off and check shafts. Then u can also replace cylinder packing and hyd. hose while in there . Then u can press the shaft out of the arm with out damage to arm.

|

|

He who dies with the most toys is,

nonetheless ,still dead.

If all else fails ,Read all that is PRINTED.

Just because you do not have the tools for job , it dose not make it a bad design.

|

|

AC720Man

Orange Level

Joined: 10 Oct 2016

Location: Shenandoah, Va

Points: 4637

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Feb 2023 at 12:39pm Posted: 11 Feb 2023 at 12:39pm |

|

If you have plans of using the 3 point for anything the housing needs to come off to see what needs to be repaired. It’s not that difficult of a job. Continuing to use it with a bush hog or other heavy equipment could result in further damage. Get a service manual and you can see how it comes apart.

|

|

1968 B-208, 1976 720 (2 of them)Danco brush hog, single bottom plow,52" snow thrower, belly mower,rear tine tiller, rear blade, front blade, 57"sickle bar,1983 917 hydro, 1968 7hp sno-bee, 1968 190XTD

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 77700

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Feb 2023 at 12:52pm Posted: 11 Feb 2023 at 12:52pm |

location is part of the problem......

The tractor is 4 hrs away on my farm and it will be a couple of weekends till I get there to work with it. I've only recently acquired the tractor so not sure what happened previously to create this situation.

At the end of the day, this is a hobby tractor for a hobby farm. Plan was to utilize this tractor for brush hogging and misc chores. |

|

Like them all, but love the "B"s.

|

|

Gatz in NE

Orange Level

Joined: 11 Sep 2009

Location: Lincoln, NE

Points: 1030

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Feb 2023 at 2:49pm Posted: 11 Feb 2023 at 2:49pm |

Is there someone at or near you farm that could try and lift up the RT arm? Other than the RT shaft having been twisted as a lot have suggested; and although not likely, if there's a great deal of free movement, it may have even sheared.

Revisiting the 1-spline index; this would be too much of a distance on the end of a 15" arm when moved one spline, compared to the picture.

|

|

AC720Man

Orange Level

Joined: 10 Oct 2016

Location: Shenandoah, Va

Points: 4637

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Feb 2023 at 9:55pm Posted: 11 Feb 2023 at 9:55pm |

|

When I twisted dad’s left shaft it didn’t break in 2, it twisted and dropped the left side. No damage was done to the rear housing. When I heard it thankfully I dropped the plow immediately. It was too late but it may have prevented further damage.

|

|

1968 B-208, 1976 720 (2 of them)Danco brush hog, single bottom plow,52" snow thrower, belly mower,rear tine tiller, rear blade, front blade, 57"sickle bar,1983 917 hydro, 1968 7hp sno-bee, 1968 190XTD

|

|

jaybmiller

Orange Level Access

Joined: 12 Sep 2009

Location: Greensville,Ont

Points: 21460

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Feb 2023 at 6:42am Posted: 12 Feb 2023 at 6:42am |

I tried counting the splines on my D-14, SC arms...15 or 16 ( fender is IN the way,kept losing count.....). Tried Google, a few pictures,but no GREAT shot of the end. Still either 15 or 16 won't make a big difference to Gatz' drawing and numbers. Sure hate to think of the force that did twist the shaft though !!!

Honestly, I'd put the tractor on a trailer and bring her home to SAFELY work on it. There is NO way I'd TRY to remove the rockshaft off without some kind of crane. Did mine, in my garaeg with overhead Ibeam, chain hoists,lotsa light, tools and it was 'ok',AFTER I dumped the diff oil into a 5G bucket....yeah that SHOULD have been 'step 1'..... While it's home,reseal the ram and add a swivelled hose while it's apart !

|

|

3 D-14s,A-C forklift, B-112

Kubota BX23S lil' TOOT( The Other Orange Tractor)

Never burn your bridges, unless you can walk on water

|

|

Mosin9130

Bronze Level

Joined: 23 Jul 2012

Location: North Texas

Points: 127

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Feb 2023 at 3:54pm Posted: 12 Feb 2023 at 3:54pm |

Thank you everyone for the help! You all have helped me realize that 1) I have an issue that most likely is a twisted shaft and that 2) I need to take the time and consideration that this won't be an easy job where the tractor sits 4 hrs from here. Without my shop built yet, my plan is to trailer the tractor down to my Dallas residence and properly delve into getting this resolved.

As others have mentioned, I can probably "live" with this for awhile so it may be Summer till I get it down (wrapping up a Land Cruiser restoration so my extra garage space is currently utilized). With that said, I did just purchase another D15 II that will be ready to "hit the ground running" so that helps buy some time as well. I did have to explain to the wife that I "needed" another D15 II though in the meantime.  |

|

'56 WD 45...'63 D15 II...'66 D17 IV

|

|

AC720Man

Orange Level

Joined: 10 Oct 2016

Location: Shenandoah, Va

Points: 4637

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Feb 2023 at 5:28pm Posted: 12 Feb 2023 at 5:28pm |

|

A good choice, it’s a really good tractor for its size. Does well with a bush hog on it

|

|

1968 B-208, 1976 720 (2 of them)Danco brush hog, single bottom plow,52" snow thrower, belly mower,rear tine tiller, rear blade, front blade, 57"sickle bar,1983 917 hydro, 1968 7hp sno-bee, 1968 190XTD

|

|

DiyDave

Orange Level Access

Joined: 11 Sep 2009

Location: Gambrills, MD

Points: 50518

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 12 Feb 2023 at 5:31pm Posted: 12 Feb 2023 at 5:31pm |

Hell, My theory is is that you need another AC tractor, for every attachment you own. That way you won't injure yourself transferring 3 point equipment, from 1 machine, to the ground, to another. Note, this does not apply to snap coupler equipment, because you don't get injured hooking SC equipment up!

|

|

Source: Babylon Bee. Sponsored by BRAWNDO, its got what you need!

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)