| Author |

Topic Search Topic Search  Topic Options Topic Options

|

GreenMule

Bronze Level

Joined: 09 Dec 2017

Location: NC

Points: 26

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 18 Dec 2017 at 7:50pm Posted: 18 Dec 2017 at 7:50pm |

|

I second what Steve said, sure hate that happen

|

|

|

Sponsored Links

|

|

|

DSeries4

Orange Level

Joined: 12 Sep 2009

Location: Ontario, Canada

Points: 7204

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 18 Dec 2017 at 8:52pm Posted: 18 Dec 2017 at 8:52pm |

jaybmiller wrote: jaybmiller wrote:

I keep shaking my head when I see the pictures...then I ask myself would you be better buying another complete running D-14 VS the cost of all the bits and pieces and shoptime to fix this engine? Pad of paper and sharp pencil time ??

I KNOW I can't afford or justify rebuilding the Buda diesel when it croaks in the forklift.

Jay

|

If the block and head check out ok, rebuild both - then you will know what you have. Getting a second hand engine is a crapshoot. Could be as good as what you already have. Parts are readily available for these engine. When built properly, you would not have to touch it again.

|

|

'49 G, '54 WD45, '55 CA, '56 WD45D, '57 WD45, '58 D14, '59 D14, '60 D14, '61 D15D, '66 D15II, '66 D21II, '67 D17IV, '67 D17IVD, '67 190XTD, '73 620, '76 185, '77 175, '84 8030, '85 6080

|

|

Don(MO)

Orange Level

Joined: 12 Sep 2009

Location: Bates City MO.

Points: 6862

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 Dec 2017 at 7:48am Posted: 19 Dec 2017 at 7:48am |

DSeries4 wrote: DSeries4 wrote:

jaybmiller wrote: jaybmiller wrote:

I keep shaking my head when I see the pictures...then I ask myself would you be better buying another complete running D-14 VS the cost of all the bits and pieces and shoptime to fix this engine? Pad of paper and sharp pencil time ??

I KNOW I can't afford or justify rebuilding the Buda diesel when it croaks in the forklift.

Jay

|

If the block and head check out ok, rebuild both - then you will know what you have. Getting a second hand engine is a crapshoot. Could be as good as what you already have. Parts are readily available for these engine. When built properly, you would not have to touch it again.

|

X2

|

|

3 WD45's with power steering,G,D15 fork lift,D19, W-Speed Patrol, "A" Gleaner with a 330 corn head,"66" combine,roto-baler, and lots of Snap Coupler implements to make them work for their keep.

|

|

Steve in NJ

Orange Level Access

Joined: 12 Sep 2009

Location: Andover, NJ

Points: 11552

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 Dec 2017 at 9:37am Posted: 19 Dec 2017 at 9:37am |

|

Bring it to ma' man Don. He'll do ya up a nice motor providing the parts check out okay...

Steve@B&B

|

|

39'RC, 43'WC, 48'B, 49'G, 50'WF, 65 Big 10, 67'B-110, 75'716H, 2-620's, & a Motorhead wife

|

|

squirt239

Bronze Level

Joined: 12 May 2017

Location: Brownsburg, IN

Points: 69

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 Dec 2017 at 11:44am Posted: 19 Dec 2017 at 11:44am |

|

Thanks for all the advice guys!

I'm a gunsmith by trade, and tinker with other stuff on the side. I have a vertical mill and lathe in the shop, and my wife's uncle owns a machine shop. He and I have discussed what to do. So here's where I am headed...you tell me if you think I'm crazy....

I've ordered and received a new piston, connecting rod, and sleeve, along with gaskets. I also ordered a valve train overhaul kit.

Currently the head is on the mill. I'm going to go ahead and "face" the head. This "should" help find any visible cracks. Next, it will be off to his shop to check for cracks in the head.

All in all, the head doesn't look THAT bad. Is there damage, yes. But I think the fact that I didn't keep forcing the motor, it prevented a lot of further damage. I've pulled the caps off the other connecting rods, and all the bearings look perfect. There's really no other metal pieces from the sleeve in the motor. I'm going to soak it with oil, and let it drain again through a coffee filter, just to be sure.

I think I can salvage this. Maybe I'm being optimistic, but it's not as bad as what I originally thought. Just going to cost me money and time!

Thanks again for all your input! This is a great forum to belong to...everyone has been very kind and very helpful!

Brett Havlin

Brownsburg, Indiana

|

|

DaveKamp

Orange Level Access

Joined: 12 Apr 2010

Location: LeClaire, Ia

Points: 5639

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 Dec 2017 at 5:48pm Posted: 24 Dec 2017 at 5:48pm |

I'll second Steve's description of the failure... with one exception: The valve broke, and bounced around in the chamber... piston found it several times, and bent the rod. THEN... the bent rod, with piston cock-eyed in the bore, shattered the sleeve, which then ventilated the coolant. With a broken sleeve and a missing valve, no substantial hydrostatic locking would occur, but it'd make quite a white cloud overhead. If it were me, I'd check the crank for damage (cracks and twist), then the block in every area near the sleeve for damage in webbing and seal faces. If it looks clean, put the lower end back together with a replacement piston and sleeve, rod, wrist pin, and rings. Milling the head... yeah, if there's a crack, that might help discover it... Fortunately, that's really good malleable iron, so it's not gonna shatter like a lesser grade casting would. It's a no-worries job... don't overthink it, don't sweat it, just dig in, make somethin' happen, and have faith and fun. For what it's worth, I've got one engine that when I was lookin' in, I noticed it had one sleeve and piston that were smaller than the rest... it obviously had a problem, and someone substituted with whatever they had from some other wreck... and it ran wonderfully, so I left it alone.

|

|

Ten Amendments, Ten Commandments, and one Golden Rule solve most every problem. Citrus hand-cleaner with Pumice does the rest.

|

|

SteveM C/IL

Orange Level Access

Joined: 12 Sep 2009

Location: Shelbyville IL

Points: 7998

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 Dec 2017 at 7:26pm Posted: 24 Dec 2017 at 7:26pm |

|

I got a con rod outta a 283 Chevy that looks like that. Broke ex valve @5800rpm one night.Destroyed piston and busted cyl wall. Valve head was stuck in piston head sideways. Made me believe in always replacing ex valves on rebuilds.

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 19546

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 Dec 2017 at 8:04pm Posted: 24 Dec 2017 at 8:04pm |

|

Do not worry about any spark plug hole cracks. They don't hurt anything. Also, if the head surface isn't quite perfect, it too won't hurt a thing. You're the only one that will ever know.

|

|

squirt239

Bronze Level

Joined: 12 May 2017

Location: Brownsburg, IN

Points: 69

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Jan 2018 at 7:15am Posted: 22 Jan 2018 at 7:15am |

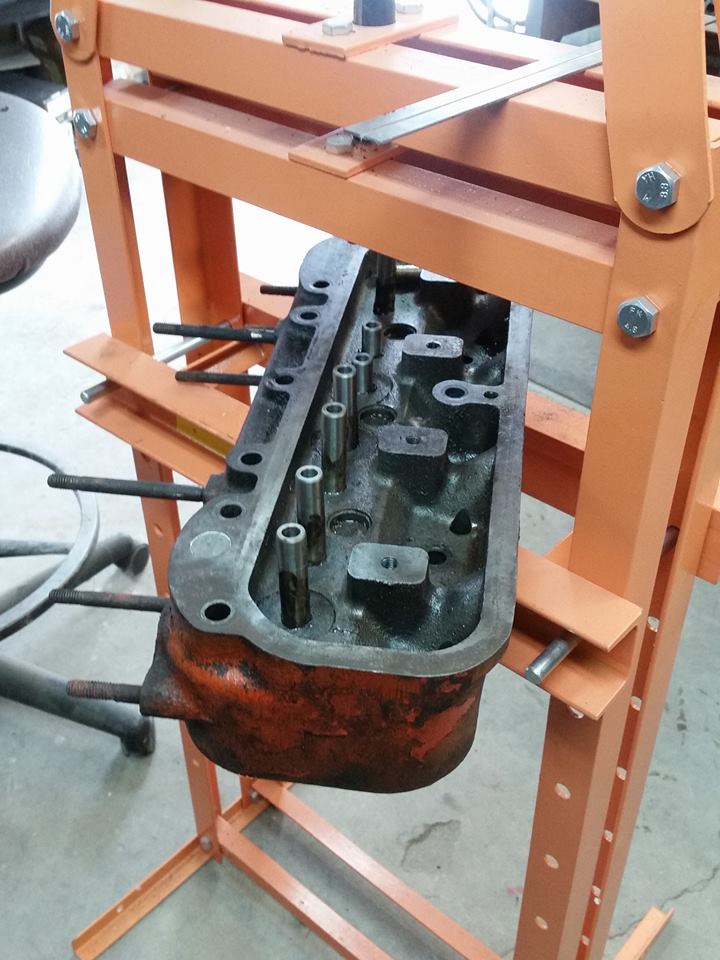

Getting some work done! All new valve guides!

|

|

squirt239

Bronze Level

Joined: 12 May 2017

Location: Brownsburg, IN

Points: 69

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Jan 2018 at 7:15am Posted: 22 Jan 2018 at 7:15am |

|

|

|

squirt239

Bronze Level

Joined: 12 May 2017

Location: Brownsburg, IN

Points: 69

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Jan 2018 at 7:21am Posted: 22 Jan 2018 at 7:21am |

Couldn't find my valve spring compressor, so I improvised.... $4000 piece of machinery to save buying a $20 tool.

|

|

squirt239

Bronze Level

Joined: 12 May 2017

Location: Brownsburg, IN

Points: 69

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Jan 2018 at 12:41pm Posted: 28 Jan 2018 at 12:41pm |

|

Weather is nice here in Indiana. Has been in the upper 40s, low 50s...in January!

Has given me the opportunity to get back to work on the D14! Today I got the block all cleaned out and up. Got all the metal out of it from the sleeve that let go. Installed the new sleeve, and new piston. Got the connecting rod on the crank and everything torqued down. I'm hoping (fingers crossed, rabbits foot in my pocket, four leaf clover in my wallet) I'll have this back up and running this week!

|

|

BenGiBoy

Orange Level

Joined: 11 Nov 2015

Location: Ashville, NY

Points: 696

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Jan 2018 at 1:53pm Posted: 28 Jan 2018 at 1:53pm |

|

Hope it goes well for you!

|

|

'39 Model B

Tractors are cheaper than girls, remember that!

|

|

Dave(inMA)

Orange Level

Joined: 12 Sep 2009

Location: Grafton, MA

Points: 2395

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Jan 2018 at 4:21pm Posted: 28 Jan 2018 at 4:21pm |

Brett, thanks for posting this story. It's good to see your progress, and I really appreciate the pictures. Sounds like you're getting close to giving it a whirl.....looking forward to hearing about that! Good luck.

Dave

|

|

WC, CA, D14, WD45

|

|

Hubnut

Orange Level

Joined: 30 Jul 2014

Location: Gainesville, FL

Points: 1812

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Jan 2018 at 4:23pm Posted: 28 Jan 2018 at 4:23pm |

|

Great post. While I hate this happened, I've enjoyed the information and rebuild.

|

|

1940 B "Lucy"

1941 B w/ Woods L59 "Flavia"

1942 B w/ finish mower "Dick"

1941 C w/ 3-point "Maggie"

1947 C SFW w/ L306 "Trixie"

1972 314H

|

|

squirt239

Bronze Level

Joined: 12 May 2017

Location: Brownsburg, IN

Points: 69

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Jan 2018 at 6:23am Posted: 30 Jan 2018 at 6:23am |

|

Head is back on! I'm going to try and get the push rods and rocker on. Hopefully set the valves today as well.

Question, though, how does one hand crank a d14? There's really no spot to put a wrench to turn it. Am I missing something?

|

|

jaybmiller

Orange Level Access

Joined: 12 Sep 2009

Location: Greensville,Ont

Points: 21486

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 30 Jan 2018 at 6:40am Posted: 30 Jan 2018 at 6:40am |

|

engage PTO, put pipe wrench on PTO shaft

REMOVE pipe wrench BEFORE starting !!! do NOT ask WHY I KNOW this....

other option

is to put a big ,bent screwdriver in the timing hole and move the ringgear,just be careful.... this is closer and since no plugs in holes is easy enough to do.

Jay

Edited by jaybmiller - 30 Jan 2018 at 6:44am

|

|

3 D-14s,A-C forklift, B-112

Kubota BX23S lil' TOOT( The Other Orange Tractor)

Never burn your bridges, unless you can walk on water

|

|

Lonn

Orange Level

Joined: 16 Sep 2009

Location: Назарово,Russia

Points: 29773

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 30 Jan 2018 at 6:52am Posted: 30 Jan 2018 at 6:52am |

|

Isn't there a hole under front grill screen for a crank to slip in? If so, and the crank pulley is right then a C Allis crank should grab the crank pulley to turn it over.

|

|

-- --- .... .- -- -- .- -.. / .-- .- ... / .- / -- ..- .-. -.. . .-. .. -. --. / -.-. .... .. .-.. -.. / .-. .- .--. .. ... -

Wink

I am a Russian Bot

|

|

squirt239

Bronze Level

Joined: 12 May 2017

Location: Brownsburg, IN

Points: 69

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Jan 2018 at 8:45am Posted: 30 Jan 2018 at 8:45am |

jaybmiller wrote: jaybmiller wrote:

engage PTO, put pipe wrench on PTO shaft

REMOVE pipe wrench BEFORE starting !!! do NOT ask WHY I KNOW this....

other option

is to put a big ,bent screwdriver in the timing hole and move the ringgear,just be careful.... this is closer and since no plugs in holes is easy enough to do.

Jay

|

HAHAHA!!! We've all had those moments. Trust me, I have had more than my fair share... Great idea! Thanks!

|

|

squirt239

Bronze Level

Joined: 12 May 2017

Location: Brownsburg, IN

Points: 69

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Jan 2018 at 8:46am Posted: 30 Jan 2018 at 8:46am |

Lonn wrote: Lonn wrote:

Isn't there a hole under front grill screen for a crank to slip in? If so, and the crank pulley is right then a C Allis crank should grab the crank pulley to turn it over.

|

There is, but I don't want to chance buying a tool that may or may not work. I think the pto trick is the way to go!!! Thanks guys!

|

|

BenGiBoy

Orange Level

Joined: 11 Nov 2015

Location: Ashville, NY

Points: 696

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Jan 2018 at 9:20am Posted: 30 Jan 2018 at 9:20am |

Just take your key out and tie it to the pipe wrench.  (Assuming you have a key, that is...  )

|

|

'39 Model B

Tractors are cheaper than girls, remember that!

|

|

squirt239

Bronze Level

Joined: 12 May 2017

Location: Brownsburg, IN

Points: 69

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Jan 2018 at 10:19am Posted: 30 Jan 2018 at 10:19am |

|

|

|

squirt239

Bronze Level

Joined: 12 May 2017

Location: Brownsburg, IN

Points: 69

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Jan 2018 at 10:20am Posted: 30 Jan 2018 at 10:20am |

Because I have been known to be a bonehead at times....

|

|

squirt239

Bronze Level

Joined: 12 May 2017

Location: Brownsburg, IN

Points: 69

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Jan 2018 at 10:30am Posted: 30 Jan 2018 at 10:30am |

|

Another question....

What tools have you used to get the two bolts on the oil pan, closest to the bell housing? I've used a wrench, but I can only move it a smidgeon each time before resetting. Tite reach? Some tool I've never heard of?

|

|

chaskaduo

Orange Level

Joined: 26 Nov 2016

Location: Twin Cities

Points: 5203

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 30 Jan 2018 at 10:40am Posted: 30 Jan 2018 at 10:40am |

|

Patience

|

|

1938 B, 79 Dynamark 11/36 6spd, 95 Weed-Eater 16hp, 2010 Bolens 14hp

|

|

BenGiBoy

Orange Level

Joined: 11 Nov 2015

Location: Ashville, NY

Points: 696

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Jan 2018 at 12:08pm Posted: 30 Jan 2018 at 12:08pm |

squirt239 wrote: squirt239 wrote:

Because I have been known to be a bonehead at times....

|

|

|

'39 Model B

Tractors are cheaper than girls, remember that!

|

|

squirt239

Bronze Level

Joined: 12 May 2017

Location: Brownsburg, IN

Points: 69

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Jan 2018 at 12:44pm Posted: 30 Jan 2018 at 12:44pm |

chaskaduo wrote: chaskaduo wrote:

Patience |

Ain't that the truth!!!

|

|

JohnCO

Orange Level

Joined: 11 Sep 2009

Location: Niwot Colo

Points: 8992

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 30 Jan 2018 at 12:54pm Posted: 30 Jan 2018 at 12:54pm |

|

Using the machine tool to install the valve springs seems like a logical thing to do. I once used a jack used to lift war heads onto air defense missiles to install an engine in my VW bus. Inspector later asked the crew where the dirty engine oil on the jack came from.......

|

|

"If at first you don't succeed, get a bigger hammer"

Allis Express participant

|

|

corbinstein

Orange Level

Joined: 31 Jul 2014

Location: Oklahoma

Points: 796

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 31 Jan 2018 at 6:41am Posted: 31 Jan 2018 at 6:41am |

|

Which Missile System John? Sounds like old Hawk Stuff. LOL

|

|

squirt239

Bronze Level

Joined: 12 May 2017

Location: Brownsburg, IN

Points: 69

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 18 Feb 2018 at 3:33pm Posted: 18 Feb 2018 at 3:33pm |

|

Today I had my 9 year old son in the garage helping me put the D14 back together. We got the push rods, rocker arms, valve cover, and thermostat and housing all back on. He was excited to help, and was awesome at helping set the initial tappet gap.

Next on the agenda is the pick up, oil pan, and putting fluids back in.

To say I'm nervous, is an under statement. But, that's we learn, right?

Spending time with the oldest boy, and teaching him a little something is worth it.

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

jaybmiller wrote:

jaybmiller wrote:

)

)